عنا

مرحبا هل يمكنني مساعدتك؟

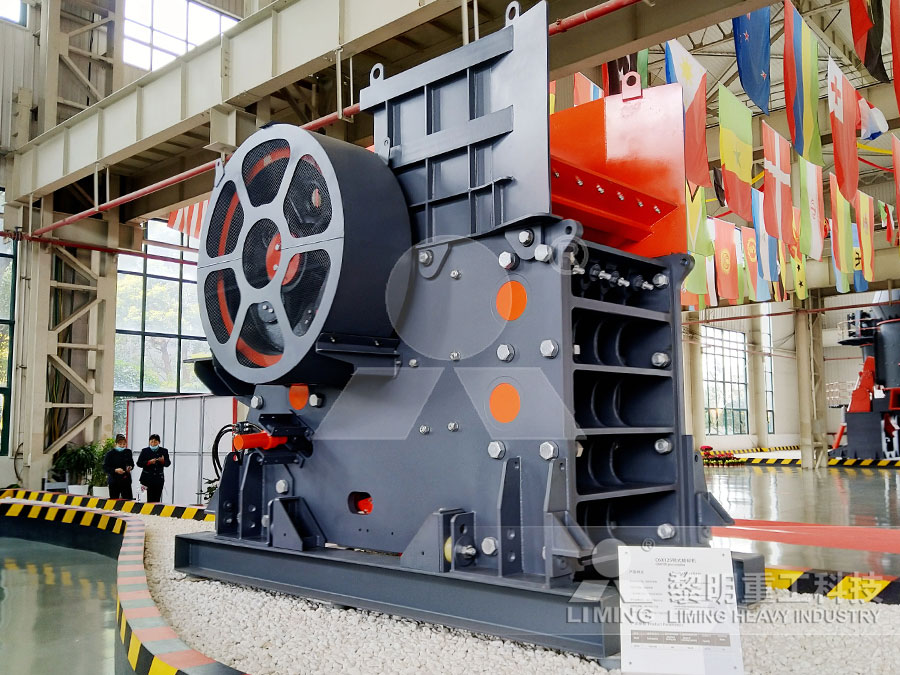

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

effectiveness of a ball mill metal ores

Ball Mill an overview ScienceDirect Topics

Ball mills give a controlled final grind and produce flotation feed of a uniform size Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is typically 75 vol% ore and 25% steelA ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellBall Mills an overview ScienceDirect TopicsJul 26, 2017 The advantages of such schemes will become more obvious when an ore of varying hardness is fed to the crushing and milling systems We will consider an ore with a ball mill work index varying between 16 and 13, feeding into a single stage ball mill operation with one million kilowatts per day consumed powerHow Ball Mill Ore Feed Size Affects Tonnage Capacity

Factors Affecting Ball Mill Grinding Efficiency

Oct 25, 2017 c) Closed Circuit Grinding – Also closely related to the ability of a ball mill to perform most effectively on a particular material size distribution is the increased grinding efficiency observed with increased circulating load and classifier efficiencyFeb 13, 2017 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the Ball Mills Mineral Processing MetallurgyJun 14, 2018 Below is the writeup of how a ball mill works, is used to crush ore and an explanation regarding its effectiveness in gold mining The Purpose of Milling First of all, in order to get the best out of how this particular equipment is used it is important to Using Ball Mills to Extract Raw Gold from Ores

Ball Mill an overview ScienceDirect Topics

Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is typically 75 vol% ore and 25% steel The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cycloneseffectiveness of a ore dressing ball mill ball mill media balls for ore dressing processing Ball Mill Media Balls For Ore Dressing Processing Ball mill Wikipedia The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silicates refractory material fertilizer glass ceramics etc as well as for ore dressing of Effectiveness Of A Ore Dressing Ball MillThe following section will take a look at some of the more common processes for creating ore concentrates Metal Recovery and Ore Concentration Techniques Stamp mills would either ship the bullion product of freemilling ores, or it would ship a concentrate, the product of more complex ores, that would need further processing at a smelterWinning the Metal: Ore Mills of the West – Western Mining

(PDF) A comparison of wear rates of ball mill grinding media

abrasive and impact wear due to their large (75 – 100 mm) dia meters Ball mill balls experience a greater number of impacts, but at lower magnitude than SAG mill balls, due t o the smaller May 22, 2019 The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force At a certain height, it will automatically fall and impact The working principle of ball mill Meetyou CarbideThe ore consumption is 023 kg / ton compared with 06 kg / ton of forging ball After reasonable matching of all elements, ratio casting qualified grinding ball blank, adopt continuous heat treatment furnace to ensure the uniformity of furnace temperature, select the appropriate quenching medium and tooling, the equipment to ensure the Heat treatment process for high chromium grinding ball

Key considerations when selecting a mill lining system

Jan 27, 2020 Figure 1: Slidingabrasion action in a Ball Mill Figure 2: Cascadingimpact action in a SAG mill Rubber and composite mill lining systems In the past, grinding mills were typically lined with cast metal linings of varying steel or iron alloys, and lining system selection was typically driven by level of wear protection and costReliable and effective grinding technology for diverse applications With more than 100 years of experience in developing this technology Outotec has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of applicationsBall mills OutotecBall mill is suitable for grinding all kinds of ores and other materials It is widely used in mineral processing, building materials and chemical industry The applicable minerals for this machine are gold, chromium, tin, tantalum, diamond, silica sand, etc Types of Ball Mills Ball mills can be divided into dry grinding and wet grindingBall mill,MQZ Ball mill China supplier,Walker mining

Quick and Easy Black Powder Ball Mill — Skylighter, Inc

Feb 14, 2018 A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls,flint pebbles Effects of slurry filling and mill speed on the net power draw of a tumbling ball mill ABSTRACT The pool of slurry is known to lower the power drawn to the mill An attempt to ascertain this observation by relating load orientation to mill power for a range of speeds and Ball Mill Research Papers AcademiaeduMost ball mills operate most efficiently between 65% and 75% of their critical speed Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant Photo of a series of ball mills in a Copper Plant, grinding the ore for flotation Image of cut away ball mill, showing material flow through typical ball mill Ball Mills Mine

Challenges in Raw Material Treatment at the Mechanical Pro

1 day ago Mineral processing for metalbearing ores In both aggregates production and the processing of rock materials, (such as crushing their performance effectiveness is relatively low and has an inverse relationship to the size of the crushed material For example, the energetic efficiency of tumble mill operation is the ball mill grinding The ball mill is the most common ore grinding technology today, and probably more than 50% of the total world energy consumption for ore grinding is consumed in ball mills(PDF) THE BENEFITS OF HIGH CLASSIFICATION EFFICIENCY IN ores, the HPGR product showed more fines and less coarse content compared to the ball mill product No conclusive evidence of preferential liberation was observed for samples prepared by particle bed(PDF) Effects of high pressure grinding rolls on platinum

Quick and Easy Black Powder Ball Mill — Skylighter, Inc

Feb 14, 2018 A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls,flint pebbles Abstract Ball milling is a simple, fast, costeffective green technology with enormous potential One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical modification of cellulose nanocrystals and nanofibersBall milling: a green technology for the preparation and Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a Ball Mill Working Principle And Main Parts

How HPGRs compare to conventional milling

Aug 19, 2019 How HPGRs compare to conventional milling Whether you’re designing a brandnew mill circuit or optimising an existing site for longterm efficiency, High Pressure Grinding Rolls offer a range of advantages over conventional milling techniques, including ball mills, SAG mills and rod millsThe ore consumption is 023 kg / ton compared with 06 kg / ton of forging ball After reasonable matching of all elements, ratio casting qualified grinding ball blank, adopt continuous heat treatment furnace to ensure the uniformity of furnace temperature, select the appropriate quenching medium and tooling, the equipment to ensure the Heat treatment process for high chromium grinding ballEffects of slurry filling and mill speed on the net power draw of a tumbling ball mill ABSTRACT The pool of slurry is known to lower the power drawn to the mill An attempt to ascertain this observation by relating load orientation to mill power for a range of speeds and Ball Mill Research Papers Academiaedu

Magnetic Separation Technology Can Improve Grinding

The effective removal of chips and scats from a ball mill leads to lower power consumption from the mill drive Eriez’ trunnion magnet can provide the solution—a powerful and efficient magnetic separator that can effectively remove as much as 80% or more of the worn/broken mediaBall mill is also widely used in the manufacturing industries, such as Biotechnology, Cement, Silicate, Fertilizer, Ferrous Metal, Nonferrous Metal and Glass Ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable materialsBall Mill – Promas Engineering Pvt Ltdore dressing mineral ball mill circuit ore dressing mineral ball mill ee The ball mill is a key equipment to grind the crushed materials and the ball mill is widely used in powdermaking production line including cement silicate newtype building material refractory material fertilizer ore dressing of ferrous metalore dressing effective mineral ball mill