عنا

مرحبا هل يمكنني مساعدتك؟

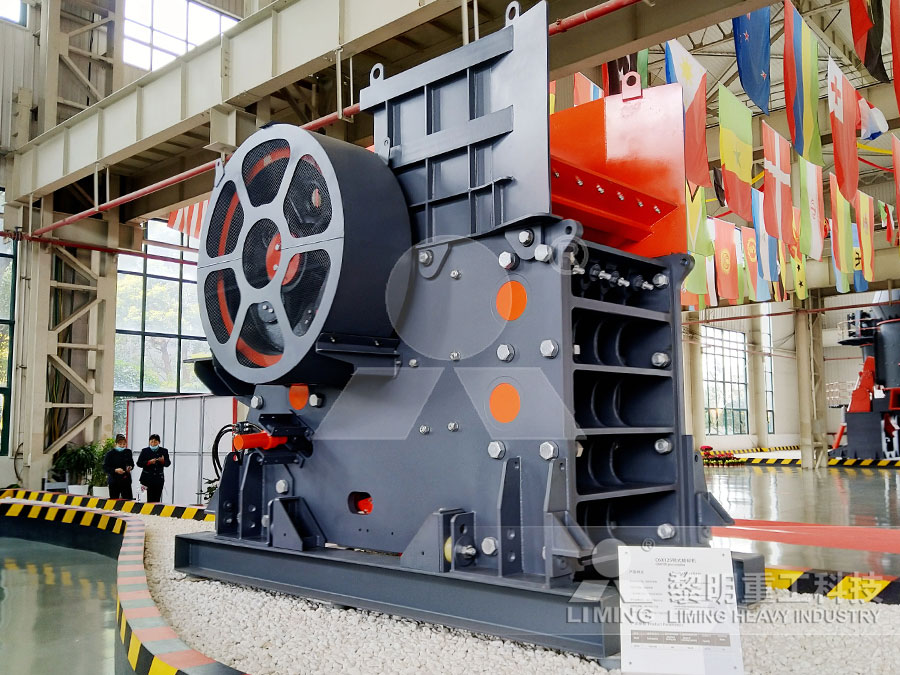

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

slag of lead and zinc ores

UGMat Nonferrous Slags Recycled Materials Resource Center

Lead, leadzinc, and zinc slags are produced during pyrometallurgical treatment of the sulfide ores The process includes three operations similar to copper and nickel slag production: 1 roasting, 2 smelting, and 3 convertingOct 13, 2017 Up to10%cash back Both lead and zinc slags are chemically and mineralogically diverse, depending on the smelting history (ie the mother ores), the smelting Lead and Zinc Metallurgical Slags Mineralogy and Lead and Zinc Smelting Industry Description and Practices Lead and zinc can be produced pyrometallurgically or hydrometallurgically, depending on the type of ore used as a charge In the pyrometallurgical process, ore concentrate containing lead, zinc, or both is fed, in some cases after sintering, into a primary smelter Lead concentraLead and Zinc Smelting IFC

Lead Slag an overview ScienceDirect Topics

Lead and lead–zinc slags are black to red in color and have glassy, sharp, and angular (cubical) particles The unit weight of granulated lead and lead–zinc slags can vary from less than 2500 kg/m 3 (156 lb cf) to as high as 3600 kg/m 3 (225lb cf)Apr 09, 2017 The ore to be smelted contained an average of about 3½ per cent, lead, 6½ per cent, iron, 2½, per cent, manganese, 7 per cent, zinc, 21 per cent, lime, 117 per cent, magnesia, 8½ per cent, silica, 1 per cent, alumina, 3 per cent, arsenic, and only a trace of sulphur, together with a very small amount of ore, which we called our lead ore Smelting of Lead Ores using High Lime SlagsThe slag runs over the top into a granulation system and is water quenched, granulated, and discarded Metal values in the slag include approximately 5% zinc and 05% lead There are limits to the level of zinc in final slag Generally zinc levels are not reduced much below 6%Zinc Ore an overview ScienceDirect Topics

Ores, slag and ash World Customs Organization

2603 260300 Copper ores and concentrates 2604 260400 Nickel ores and concentrates 2605 260500 Cobalt ores and concentrates 2606 260600 Aluminium ores and concentrates 2607 260700 Lead ores and concentrates 2608 260800 Zinc ores and concentrates 2609 260900 Tin ores and concentrates 2610 261000 Chromium ores and concentrates 2611 261100 Tungsten ores and Slag and lead collect at the bottom of the furnace and are tapped off regularly The zinc is scrubbed from the vapour in the condenser via liquid lead The liquid zinc is separated from the lead in Zinc smelting WikipediaSlag is the glasslike byproduct left over after a desired metal has been separated (ie, smelted) from its raw oreSlag is usually a mixture of metal oxides and silicon dioxideHowever, slags can contain metal sulfides and elemental metals While slags are generally used to remove waste in metal smelting, they can also serve other purposes, such as assisting in the temperature control of Slag Wikipedia

Lead and Zinc Energy

611 Lead and Zinc Ore Mining Lead and zinc ore is nearly always mined below the surface of the ground Some veins of ore lie as deep as several thousand feet but most deposits lie close to the surface Lead and zinc ore is mined almost exclusively in underground operations, though a few surface operations do existOres, slag and ash Notes 1 This Chapter does not cover : compounds (for example, tetraethyl lead), and consisting essentially of lead, lead compounds and iron oxide 2 Slag, ash and residues containing arsenic, mercury, thallium or their mixtures, of a kind used for the 2608 260800 Zinc ores and concentratesOres, slag and ash World Customs Organization611 Lead and Zinc Ore Mining Lead and zinc ore is nearly always mined below the surface of the ground Some veins of ore lie as deep as several thousand feet but most deposits lie close to the surface Lead and zinc ore is mined almost exclusively in underground operations, though a few surface operations do existLead and Zinc Energy

Lead and Zinc Metallurgical Slags Mineralogy and

Oct 13, 2017 Both lead and zinc slags are chemically and mineralogically diverse, depending on the smelting history (ie the mother ores), the smelting technologies and the flux minerals The Pb and Zn concentration in slags indicates the recovery efficiency of the smelting technologies, the presence of S indicates if the mother ores are rich in either Pyrometallurgical slag, produced 100–150 years ago from lead–zinc ores in the smelting region of Příbram, Czech Republic, contains elevated amounts of Zn and Pb Knowledge of the distribution of these elements in the main phases and an investigation of natural weathering features represent the first step in the environmental assessment PRIMARY PHASES AND NATURAL WEATHERING OF OLD LEAD–ZINC richest producer of lead and zinc ores More importantly, it was located next to the coal fields of southeastern Kansas Coal was essential for smelting, the process of removing spelter—metallic zinc—from ore The first zinc smelter in Kansas was built in Wier City in 1870 The Edgar Zinc Kansas Department of Health and Environment

126 Primary Lead Smelting

126 Primary Lead Smelting 1261 General15 Lead is found naturally as a sulfide ore containing small amounts of copper, iron, zinc, precious metals, and other trace elements The lead in this ore, typically after being concentrated at or near the mine (see Section 1218), is processed into metallurgical lead at 4 facilities in the U SLead processing Lead processing Mining and concentrating: Once the ore is removed from veins (narrow channels) or lodes (roughly spherical deposits) in the Earth, usually at depths of about 60 metres, the ore is treated at concentrating mills Here the ore is finely crushed, sometimes to particle diameters of less than 01 millimetre (0004 inch), and then treated by one of several mineral Lead processing Mining and concentrating BritannicaThe zinclead blast furnace Sintered zinc and lead concentrates, mixed with metallurgical coke, are charged into the top of a shaft furnace, into which preheated air is blown through nozzles, or tuyeres, at the base (see figure)This procedure is similar to that followed in an iron blast furnace, with the important difference that the major products of reduction here are a zincbearing gas zinc processing The zinclead blast furnace Britannica

Chapter26 Ores, slag, ash, Iron ore HS Code Eximdata

Chapter26 Ores, slag and ash, copper ore hs code, aluminium, titanium, zinc, lead, nickel, iron ore HS Code 2601 Iron ore HS code and concentrates, including roasted iron pyrites Iron ores and concentrates, other than roasted iron pyrites HSN codeSep 20, 2018 Lead is found in the mineral galena (PbS) and ores of copper, zinc, and silver Lead is highly toxic The element primarily affects the central nervous system It is particularly dangerous to babies and children, where lead exposure can stunt development Lead is a cumulative poison10 Lead Element Facts (Pb or Atomic Number 82)Jan 01, 1998 Lead concentrations can be 50–70%, and the sulfur content of sulfidic ores is in the range of 15–20% Zinc concentration is in the range of 40–60%, with sulfur content in sulfidic ores in the range of 26–34% Ores with a mixture of lead and zinc concentrate usually Lead and Zinc Smelting Industry Pollution Prevention

LEAD ZINC EXTRACTION PROCESSES

are used for production of lead zinc depending on the type of raw material used as a charge In the pyrometallurgical process, ore concentrate containing lead, zinc, or both is fed, in some cases after sintering, into a primary smelter Lead concentrations can be 5070%, and the sulfur content of sulfidic ores is in the range of 1520%ORES, SLAG AND ASH V 261 Notes 1 This chapter does not cover: (a) Slag or similar industrial waste prepared as macadam (heading 2517); (b) Natural magnesium carbonate (magnesite), whether or not calcined (heading 2519); lead or zinc content, an absolute deduction for losses of 18 kgORES, SLAG AND ASH V 261 NotesDec 15, 2010 Mine tailings are the ore waste of mines, and are typically a mudlike material Worldwide, the storage and handling of tailings is a major environmental issue Many tailings are toxic and must be kept perpetualy isolated from the environment Scale of tailings production is immense, since metal extraction is usually only ounces or pounds, for Mine Tailings

PRIMARY PHASES AND NATURAL WEATHERING OF OLD LEAD–ZINC

Pyrometallurgical slag, produced 100–150 years ago from lead–zinc ores in the smelting region of Příbram, Czech Republic, contains elevated amounts of Zn and Pb Knowledge of the distribution of these elements in the main phases and an investigation of natural weathering features represent the first step in the environmental assessment industrialization has attracted the attention of scientists regarding its proper disposal LeadZinc Smelting Slag (LZSS) is an industrial waste produced during the smelting of lead (Pb) and zinc (Zn) from their ores It is considered hazardous waste as to it contains a number of heavy metals including Pb, Zn, Cu, Mn, Cr, Cd and Ni etcThe Solidification of LeadZinc Smelting Slag through ORES, SLAG AND ASH V 261 Notes 1 This chapter does not cover: (a) Slag or similar industrial waste prepared as macadam (heading 2517); (b) Natural magnesium carbonate (magnesite), whether or not calcined (heading 2519); lead or zinc content, an absolute deduction for losses of 18 kgORES, SLAG AND ASH V 261 Notes

Zinc Recovery Mineralogical Reconstruction of Lead

The lead smelter slag may be regarded as an important secondary resource, since tons of the slag containing 10 to 25 % Zn, 3 % Pb and other minor valuable elements are dischargedrichest producer of lead and zinc ores More importantly, it was located next to the coal fields of southeastern Kansas Coal was essential for smelting, the process of removing spelter—metallic zinc—from ore The first zinc smelter in Kansas was built in Wier City in 1870 The Edgar Zinc Kansas Department of Health and EnvironmentIn the smelting process of lead and zinc ores, As 2 O 3 and As 2 O 5 are emitted in the flue gases from the smelting/roasting furnaces; gases are treated, and the pollutants are washed into the acid sewage By the sulfide precipitation method of the acid sewage, arsenic sulfide slag is producedOxidation Treatment of Arsenic Sulfide Slag

Lead and Zinc Metallurgy SpringerLink

Jul 31, 2015 The two metals are closely connected, starting with their mineralogical occurrence in combined leadzinc ores (ie, combination of mainly lead sulfide, zinc sulfide, iron sulfide, iron carbonate, and quartz) that are processed in the primary industry and hence interlink the production routes Both metals have very high recycling rates6 Lead and Zinc Mziyanda shumi Energy and Environmental Profile of the US Mining Industry 6 Lead and Zinc Lead and zinc ores are usually found together with gold and silver A leadzinc ore may also contain lead sulfide, zinc sulfide, iron sulfide, iron carbonate, and quartz When zinc and lead sulfides are present in profitable amounts (PDF) 6 Lead and Zinc Mziyanda shumi AcademiaeduChapter26 Ores, slag and ash, copper ore hs code, aluminium, titanium, zinc, lead, nickel, iron ore HS Code 2601 Iron ore HS code and concentrates, including roasted iron pyrites Iron ores and concentrates, other than roasted iron pyrites HSN codeChapter26 Ores, slag, ash, Iron ore HS Code Eximdata

zinc processing The zinclead blast furnace Britannica

The zinclead blast furnace Sintered zinc and lead concentrates, mixed with metallurgical coke, are charged into the top of a shaft furnace, into which preheated air is blown through nozzles, or tuyeres, at the base (see figure)This procedure is similar to that followed in an iron blast furnace, with the important difference that the major products of reduction here are a zincbearing gas The invention discloses a process for recycling ion from leadzinc smelting waste The process is characterized by comprising the following steps: adding an interface modifier, leadzinc smelting waste and lime into water, and uniformly stirring to obtain a mixture aqueous solution of iron colloid and gypsum; adding an iron colloid interface adsorbent, a foaming agent and a gypsum interface CNA Process for recycling ion from leadzinc Lead processing Lead processing Mining and concentrating: Once the ore is removed from veins (narrow channels) or lodes (roughly spherical deposits) in the Earth, usually at depths of about 60 metres, the ore is treated at concentrating mills Here the ore is finely crushed, sometimes to particle diameters of less than 01 millimetre (0004 inch), and then treated by one of several mineral Lead processing Mining and concentrating Britannica

Zinc: smelting, producing and classificationMetalpedia

Typically, a zinc concentrate contains about 55% of zinc with some copper, lead and iron Zinc concentration is usually done at the mine site to keep transport costs to smelters as low as possible Zinc smelting Zinc smelting is the process of converting zinc concentrates (ores that contain zinc) into pure zincMay 15, 2020 The main ores of zinc are: (i) Zinc blende ZnS (ii) Calamine ZnCO 3 (iii) Zincite ZnO (iv) Franklinite ZnOFe 2 O 3 (v) Willemite Zn 2 SiO 4 The principal ore of zinc is zinc blende Extraction: Zinc can be extracted from zinc blende by the following steps: 1) Concentration: The ore is concentrated by froth floatation processExtraction of Copper and Zinc Chemistry, Class 12