عنا

مرحبا هل يمكنني مساعدتك؟

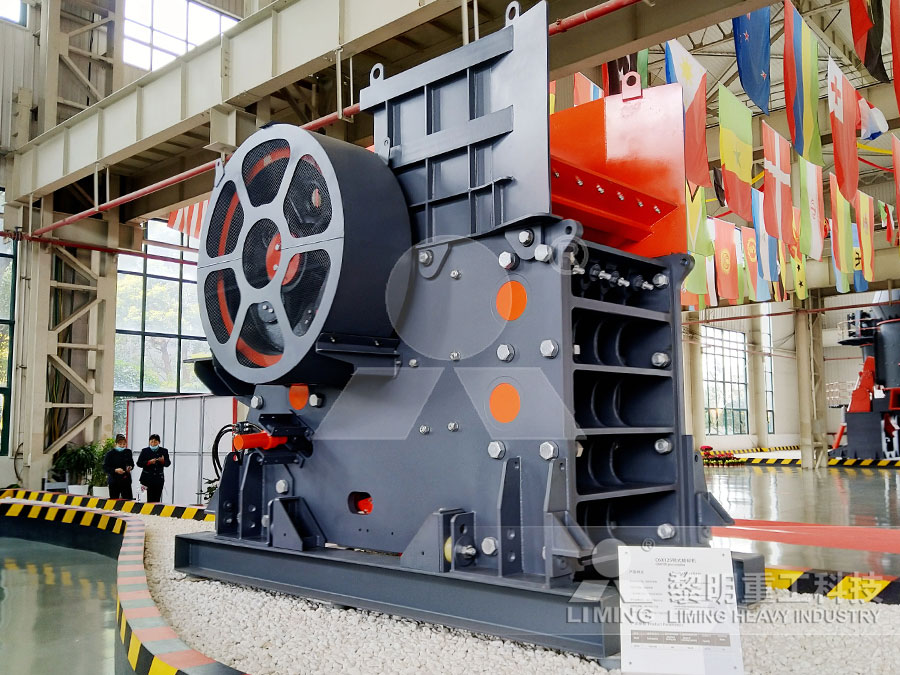

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

grinding machine and mponets

Parts of a Grinding machine and their functions

May 29, 2020 This grinding machine part consists of a grinding wheel and a driving motor The wheel head is mounted on a slide at the rear end of the base and moves perpendicularly to the table ways This is done by power or hand when feeding the grinding wheel to the workJun 23, 2020 Centerless Grinding of Precision Machined Components To modify the outside diameter (OD) of a precision machined component, there are two types of cylindrical surface grinding operations that can be used: centerless and centeredCenterless Grinding of Machined Components Pioneer A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial It is a process of metal cutting by using a rotating abrasive whee l from the surface of the workpiece Generally, the grinding is finishing operation to show Grinding Machine: Types, Parts, Working Operations (With

About this site

Jun 26, 2015 The components on a basic ID grinding machine that need alignment maintained are the slides, both “X” and “Z,” the grinding wheel spindle, the grinding wheel truing/dressing device and the workhead spindle Each component should be aligned correctly and checked to ensure they achieve the following requirements:Mar 27, 2021 Cylindrical grinders are big size grinders which are used to grind heavy parts The main components of this type of grinder are base, bed, headstock, tailstock, work table and grinding wheel The work piece is mounted on the Chuck of the headstock When Chuck rotates the work, piece is also rotatingTypes of Grinding Machine: Parts, Working Principle Jun 29, 2020 Special types of grinders are grinding machines made for specific types of work and operations, for example: Tool and cutter grinders These grinding machines are designed to sharpen milling cutters, reamers, taps and other machine tool cutters The generalpurpose cutter grinder is the most popular and versatile toolgrinding machineAbout this site

14 Types of Grinding Machines [Working, Diagram PDF]

May 25, 2021 Portable Grinder 25 5 Flexible Grinder 26 6 Precision Grinder Machines in which grinding wheels are fitted and grinding is done, such machines are called grinding machines On the basis of their function, they can be divided into two partsMany grinding machine spares in stock Including: Workheads, Tailstocks, Spindles, spare parts, Drives, Pumps, Dressers and Servo motors Amplifiers (13) Monitors (1) Parts (85)Grinding Machine Spares New and Refurbished PartsWebsite Directions More Info (503) 5814220 1520 Hickory St NE Salem, OR 97301 From Business: Since 1977 we have been helping businesses with their needs of manufactured parts needing OD grinding to spec and we are located at 1510 Hickory St NW in Salem 9 Industrial Carbide Tooling Inc Saw Sharpening Repair Precision GrindingAbout this site

Cylinder Head Supply

ZERO Blast Cabinets and Parts; CLEARANCE ITEMS; Used Equipment; New Products; Cylinder Honing Neway Valve Seat Cutting Valve Guide Tools Valve Seat Grinding Valve Grinding Sign up for new product releases, updates and sales WOODWARD EQUIPMENT CHS 15790 SE Piazza Ave STE104 PO Box 2650 Clackamas, OR 97015 USA Telephone: +1 5036576680 Fax It is a cover of an abrasive wheel or grinding wheel which protects the worker in any type of accident—grinding machine parts and functions #6 Abrasive Wheel HeadIt is a compartment that is moved up or down using a traversing wheel called a vertical feed handwheel We push this wheel head forward so that the grinding Parts and Functions of Grinding Machine Grinding Machine Jun 15, 2019 Grinding Machine Parts and Functions 6) Wheel Head :It is the compartment that is moved vertically up or down using a traversing wheel called Vertical Feed Hand Wheel We move this wheel head so that the grinding wheel can touch Grinding Machine Parts And Functions Mechanical Walkins

14 Types of Grinding Machines [Working, Diagram PDF]

May 25, 2021 Portable Grinder 25 5 Flexible Grinder 26 6 Precision Grinder Machines in which grinding wheels are fitted and grinding is done, such machines are called grinding machines On the basis of their function, they can be divided into two partsJun 23, 2020 In Centerless grinding, the grinding wheel is stationary The part moves through the machine and past the grinding wheel, which removes the material from the part This process is used when the part can not have centers added to the ends of the component Pioneer Service has inhouse capabilities for centerless grindingCenterless Grinding of Machined Components Pioneer Jul 04, 2021 It is the most important parts of surface grinding machine by which perform different operations Most often the following grinding wheels are used: (a) Straight (b) Double raised (c) Thin rubber slotting wheels, etc Usually, the grinding wheel size is 250 mm in diameter and 25 mm in a face The grinding wheel size can be increased according Surface Grinding Machine Parts and Function,Types,Uses

Commercial Grinding Machine Parts Industrial Lathe Parts

While we do offer numerous replacement parts and full rebuilds, there's a time when you're spending more money to keep the machine running than the machine is worth For example, a broken spindle would cost over $20,00000 to repair; this amount could instead be a payment for a replacement New machines provide advanced functions and easier useRadial Drilling Machine: Definition, Diagram, Parts, Working, Advantages, Disadvantages, and Applications [PDF] Drilling Machine is used to make circular holes on the components with the help of Drill bits In the last article, we had discussed the Drilling Machine, Surface Grinding Machine, Milling Machine, lathe machine, etc whereas, in Today's article, weSurface Grinding Machine: Definition, Parts, Working Grinding Machines Setting the standard for highproduction applications requiring longterm machining accuracy As a global leader in grinding machine technology, Toyoda offers an extensive lineup of highperformance universal, cylindrical, camshaft, and crankshaft grinding machinesToyoda Grinding Machines

UNITED GRINDING North America Precision Grinding Machines

Mar 09, 2021 Vertical grinding machines; Show all machines UNITED GRINDING North America 0 Product Technology Groups 0 Brands 0 Employees UNITED GRINDING North America: Who We Are and What We Do Latest News All articles UNITED GRINDING 09 March 2021 UNITED GRINDING Adds New Automation to Old WALTER Grinders Versatile, Reliable, Adjustable For more than 60 years, Bader has set the standard for elegant design, safety and durability USAmade, family strongHome page Stephen Bader Inspiring grinder envyTo manufacture these components in a high quality, the grinding process and clamping technology must be fast and extremely precise Special clamping solutions ensure that even small and collisioncritical components, such as drive shafts with a module of 06 in a gear quality of DIN 14, can be machined without difficultyGrinding for emobility Gear cutting technology

parts of grinding machine, parts of grinding machine

129,393 parts of grinding machine products are offered for sale by suppliers on Alibaba, of which grinding equipment accounts for 15%, other food processing machinery accounts for 8%, and flour mill accounts for 7% A wide variety of parts of grinding machine options are available to Grinding Machine Definition: A grinding machine is a production machine tool used in the manufacturing industry in which the grinding wheel is attached in the tool post and the workpiece is fixed to the work table and when the operation starts it removes the Grinding Machine: Definition, Parts, Working Principle Grinding Specialists Since 1965 We have over 50 years of high quality precision grinding experience Specializing on OD ID grinding, surface rotary grinding, multiprocess OD ID vertical grinding, centerless grinding, ID honing, flat lapping and repairs Let us be the only precision grinding services provider you will ever need Our StoryGrindal Company OD ID Precision Grinding Specialists

Toyoda Grinding Machines

Grinding Machines Setting the standard for highproduction applications requiring longterm machining accuracy As a global leader in grinding machine technology, Toyoda offers an extensive lineup of highperformance universal, cylindrical, camshaft, and crankshaft grinding machinesThe PG9BHD is a hydraulicallydriven centerless Form grinding machine designed to form multiple components from rod or preformed parts Examples of parts ground on this machine include carbon fiber and Teflon® (PTFE) components, golf balls, check valves, drumsticks, deodorant balls, pen nibs, ceramic balls, rubber balls, billiard balls, and moreCenterless Grinders Glebar Precision Centerless Grinding Wide Belt Grinding Machine SP1300 Wide Belt Grinding Machine is a very versatile machine model This series of models is just like the principle of Tai Chi, combining rigidity and flexibilityThe planetary abrasive barrel station that consists of 6 abrasive barrels (3 in clockwise rotation, and 3 in counterclockwise rotation) will further rounds the edges and the contoursSheet Metal Deburring Machines Wide Belt Grinding

IDENTIFYING MACHINE PARTS AND THEIR FUNCTIONS – Cad

On the universal cylindrical grinder (Figure L112), both the wheelhead and table may be swiveled for taper grinding All possible motions are illustrated in Figure L113 Major Parts of the Universal CenterType Cylindrical Grinder Major parts of the machine include the bed, slide, swivel table, headstock, footstock, and wheelheadWhile we do offer numerous replacement parts and full rebuilds, there's a time when you're spending more money to keep the machine running than the machine is worth For example, a broken spindle would cost over $20,00000 to repair; this amount could instead be a payment for a replacement New machines provide advanced functions and easier mercial Grinding Machine Parts Industrial Lathe PartsMar 09, 2021 Vertical grinding machines; Show all machines UNITED GRINDING North America 0 Product Technology Groups 0 Brands 0 Employees UNITED GRINDING North America: Who We Are and What We Do Latest News All articles UNITED GRINDING 09 March 2021 UNITED GRINDING Adds New Automation to Old WALTER Grinders UNITED GRINDING North America Precision Grinding Machines

Grinding Machines an overview ScienceDirect Topics

Grinding machines, like broaching machines, operate over a range of speeds depending on the type of machine being usedThese range from approximately 1250 to 2000m min −1, although in highspeed grinding speeds of up to 5400m/min are achievable (Schey, 1987)The two most common grinding applications are cylindrical grinding and surface grindingWe provide parts for the small, but wellbuilt Micromaster surface grinder and all other models of their surface grinders We also provide parts for Brown Sharpe milling machines This means that we can keep your surface grinder or milling machine running in great shape for decades, no matter when it OEM Repair Parts for Brown Sharpe Surface GrindersTo manufacture these components in a high quality, the grinding process and clamping technology must be fast and extremely precise Special clamping solutions ensure that even small and collisioncritical components, such as drive shafts with a module of 06 in a gear quality of DIN 14, can be machined without difficultyGrinding for emobility Gear cutting technology

Used Grinding Machines Industrial Metal Grinders

Bore grinding machines Bore grinding machines are used to bore holes in metal, stone and wood This type of machine is also offered by budget manufacturers and is designed for private use Professional bore grinding machines for industrial use are manufactured by FARMAN, FROEHLICH, KLINGEL, SCHANBACHER and SCHLUMBERGERThis machine is used to produce external cylindrical surface The surfaces may be straight, tapered, steps or profiled Broadly there are three different types of cylindrical grinding machine as follows: 1 Plain centre type cylindrical grinder 2 Universal cylindrical surface grinder 3 Centreless cylindrical surface grinderTypes of Grinding Machines LearnMechA grinding machine, often shortened to grinding machines, is one of power tools or machine tools used for grinding, it is a type of machining with a grinding wheel as a cutting tool Highly static, dynamic and good thermal symmetrical behaviour is achieved through the compact design of the machine components as well as the use of cast iron Top Grinding Machine Manufacturing Companies [List]