عنا

مرحبا هل يمكنني مساعدتك؟

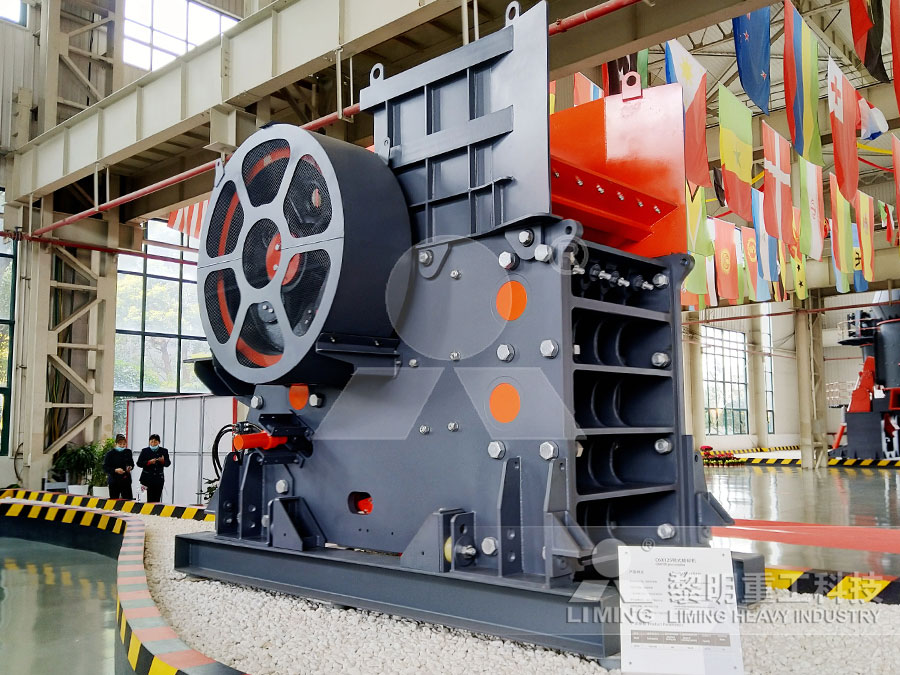

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

working principle of grinding machine

Working principles of machine studentlesson

The working of a machine is quite interesting due to the fact that it is a computer base The machine works based on CAD and CAM programs as well as computer control just as earlier mentioned, the CAD (ComputerAided Diagram) is a drawing software of the item to be produced, which serves as a carboncopy of the product The principles of operation Movement of X, Y, Z axis are controlled by a motor which supplies either Alternating current or Direct current Movement of the machine is done by giving commands All the operations are carried out by codes like speed, feed, depth of cut, etcWhat Is the Working Principle of A and Types of Working Principle Of systems Computer numerical control machine tools are such type of machine tools that have revolutionized machining processes It is nothing but using a computer as a mean to control a machine that produces useful What Is Machine? Working Principle Of systems

What is Machining? Its Working Principle and

machines use digital instructions (such as GCode or MCodes) to move and tool and workpiece in a machine For machining, the Operator firstly loads digital instructions ( Program) and fixes the workpiece in the machine Afterward, machines perform required machining operations automatically with minimal operator interference Working Principle of Machine It consists of two separate controls, a controller that doses the function of program decoding interpolation, diagnostics machine actuation, etc Another is the programmable logic controller (PLC), which does spindle onoff, coolant onoff, turret operation, C Machine: How it Works? Parts, Types, Feature with [PDF] Milling machine will have one spindle and one reciprocating adjustable working table Spindle will be driven by electrical motor and it will mount and rotate the milling cutter Working table will mount the workpice and insert against rotating cutter Working Principle of Milling machining WORKING PRINCIPLE AND TYPES OF MILLING MACHINE

grinding machines – grindaix GmbH

grinding machines are machine tools which use a rotating grinding wheel to achieve material removal on a metallic workpiece by means of cutting Grinding machines are mostly used for the hardfine machining of workpieces (parts)Grinding machine operation is also carried out for machining too hard material Working principle of Grinding Machine: The working principle of a grinding machine is quite easier to understand In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulleyGrinding Machine: Types, Parts, Working Operations (With Working principle of cylindrical grinder Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Working principle of cylindrical grinder, quarry, aggregate, and different kinds of mineralsWorking principle of cylindrical grinder

Machine: Types, Parts, Advantages, Disadvantages

The Machine has Higher Production and capability It can run for 24 hours a day Reliable Disadvantages of Machine: Here are some disadvantages of machine: The installation cost is high Even do the parts of the machine are high When any failure occurs in the machine the high skilled profession requires to solve the issue Any machine that can move tool head and workpiece automatically is known machine Different types of machines have different cutting tools and tool or workpiece motion in different directions Therefore any machine that utilizes digital codes to move a workpiece or tool is a Machine For example, even a 3D printer is a type of What is Machining? Its Working Principle and Working principle of Grinding Machine: The working principle of a grinding machine is quite easier to understand In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley So when we start the electric motor the motor rotates at a certain rpm (15015000 RPM, it may change according to the types of grinding Grinding Machine: Types, Parts, Working Operations

What Is Machine? Working Principle Of systems

Working Principle Of systems Computer numerical control machine tools are such type of machine tools that have revolutionized machining processes It is nothing but using a computer as a mean to control a machine that produces useful objects from solid blocks of material machine Cylindrical Grinding machine about the fundamentals and objective of cylindrical grinding machine, we have also seen various parameters which must be measure on cylindrical ground and various sensors used for smooth operation of CGM WORKING PRINCIPLE AND TYPES OF MILLING MACHINE The Machine has Higher Production and capability It can run for 24 hours a day Reliable Disadvantages of Machine: Here are some disadvantages of machine: The installation cost is high Even do the parts of the machine are high When any failure occurs in the machine the high skilled profession requires to solve the C Machine: Types, Parts, Advantages, Disadvantages

What Is a Machine? Block Diagram Parts of

The term stands for ‘computer numerical control,’ and the definition of machining is that it is a substandard manufacturing process that typically employs computerized controls and machine tools to remove layers of material from stock grinding — which Known as a blank or workpiece — and produces a customdesigned part machining is a reductive machine process in which the stock material is drawn out 3D printing process, on the other hand, is a reverse functioning additive process in machining machines were first developed in the (194050)s, and primarily based on the “punched tape” data storage technique The program code for the machine What is a Machine and How does Machines For the operators of grinding machine, they need to pass the examination and obtain the corresponding operation certificate before they can carry out the normal operation of grinder At the same time, before operating the grinder, it is necessary to have a certain understanding of the structure and working principle of the grinderOperation steps and precautions of grinder(

12 Different Types Of Machine [Complete Guide] PDF

It is a precision performance tool that uses a rotating wheel to cut metal away from the metal Typically, grinding machines are used for camshafts, ball bearings, transmission shafts, and other working pieces, which require an accurate and correct finish Numerous pieces made using a grinding machine Working principle of Machining system In this article, we will learn about Machining System: Working Principle Advantage Disadvantage Computer numerical controlled () machines are machines that control all the movements of NC machines using a computer and are used to produce the C Machining System: Working Principle Advantage For the operators of grinding machine, they need to pass the examination and obtain the corresponding operation certificate before they can carry out the normal operation of grinder At the same time, before operating the grinder, it is necessary to have a certain understanding of the structure and working principle of the grinderOperation steps and precautions of grinder(

roll grinding working principle vierenmetzorgnl

working principle of grinding machine working principle grinding machine vibrating sieve separator Grinding machine ore crusher price the free encyclopedia A grinding machine often shortened to grinder is a machine tool used for grinding which is a type of machining using The small NC milling machine consists of five parts: numerical control system, testing device, a driving device, transmission chain of the machine tool and servo motor Each part has a special function, the following from the five parts of their respective working principle, we have a certain understanding of the small milling machineWorking Principle Of Small Milling Machine in China Working principle of Machining system In this article, we will learn about Machining System: Working Principle Advantage Disadvantage Computer numerical controlled () machines are machines that control all the movements of NC machines using a computer and are used to produce the C Machining System: Working Principle Advantage

grinding machines – grindaix GmbH

The grinding wheel is the actual tool of the grinding machine Grinding wheels are rotationally symmetric tools whose abrasive grits are held together by means of a bond The sharp edges of the abrasive grits remove material by means of cutting when they come into contact with the part to be ground Grinding machining is a reductive machine process in which the stock material is drawn out 3D printing process, on the other hand, is a reverse functioning additive process in machining machines were first developed in the (194050)s, and primarily based on the “punched tape” data storage technique The program code for the machine What is a Machine and How does Machines It is a precision performance tool that uses a rotating wheel to cut metal away from the metal Typically, grinding machines are used for camshafts, ball bearings, transmission shafts, and other working pieces, which require an accurate and correct finish Numerous pieces made using a grinding machine 12 Different Types Of Machine [Complete Guide] PDF

What Is a Machine? Block Diagram Parts of

The term stands for ‘computer numerical control,’ and the definition of machining is that it is a substandard manufacturing process that typically employs computerized controls and machine tools to remove layers of material from stock grinding — which Known as a blank or workpiece — and produces a customdesigned partDESIGN OF GRINDING MACHINES Our technical department designs grinding machines on a daily basis according to the specific requirements of our customers One of our strengths lies in the many years of experience gained in the design and production of machines and industrial robots We use the latest 3D CAD design programsDesign of grinding machinesWorking principle of surface grinder Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Working principle of surface grinder, Working principle of surface grinder