عنا

مرحبا هل يمكنني مساعدتك؟

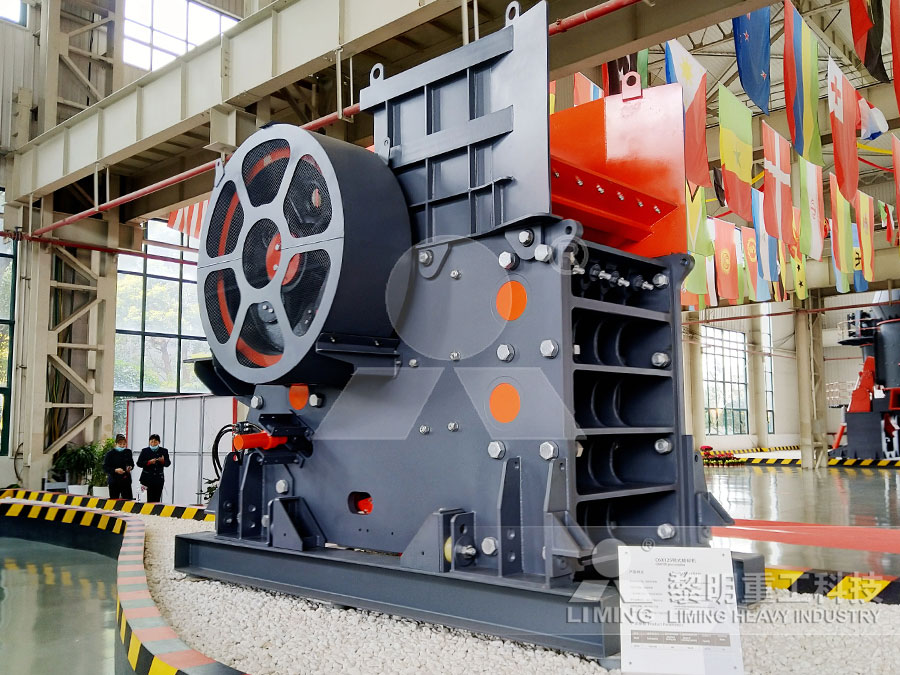

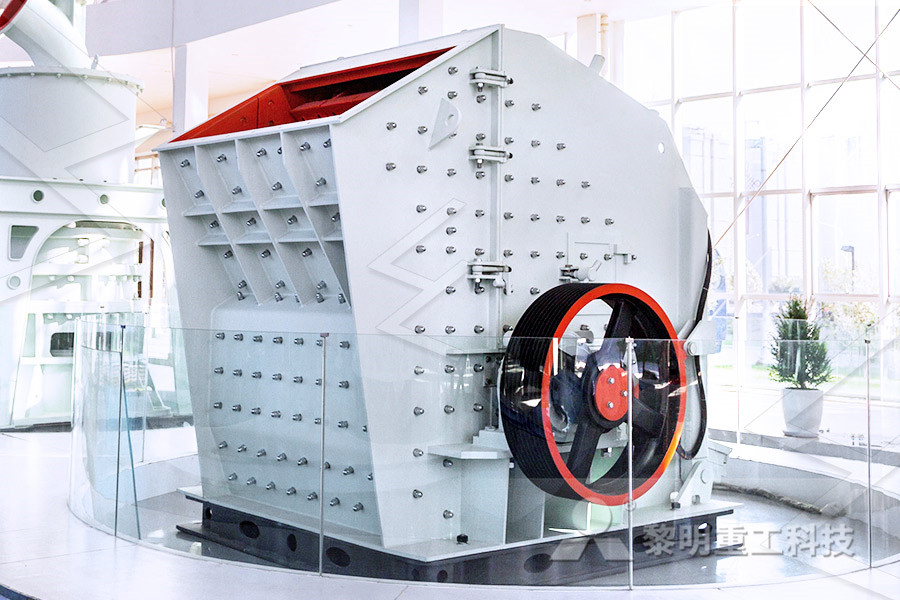

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Method Of Gold Metal Revery In Ore

Gold Extraction Recovery Processes

Some of the metallurgical relationships that must be considered from the testwork program as follows: ore grade relationship to gold recovery, crushing and grinding parameters and their relationship to the ore variability in the ore Placer gold ore with high gold content mostly exists in the form of particles Therefore, the ideal method to process placer gold ore is gravity separation Rock gold ores have a more complex composition than placer gold ores’, thus whether to choose gravity separation and flotation separation depends on the specific composition5 Gold Extraction Methods to Improve Your Recovery Rate Gold recovery using this technique is pH sensitive, and five pH values (20, 36, 40, 54, and 60) were investigated FA analysis showed the Shanono gold ore deposit contains an average of 471 ppm of gold, AAS analysis showed highest gold recovery of 69% at pH 40, which is lower than recoveries from the metal scrapsRecovery of Gold from Shanono Gold Ore Deposit Using α

Leaching and recovery of gold from ore in cyanidefree

A gold ore sample originated from an epithermal deposit with a composition shown in Table 2 was used as a feed material in the leaching experiments Xray fluorescence and inductively coupled plasma optical emission spectrometry (ICPOES; Thermo Scientific iCAP 6000, USA) were used to determine the chemical composition of the sample after total dissolution, whereas gold and silver were A Method for Leaching or Dissolving Gold From Ores or Precious Metal Scrap during the precipitation stage for the recovery of gold from precious metal scrap Gold Ore with Cyanide and A Method for Leaching or Dissolving Gold From Ores or Bioleaching is a conversion of an insoluble valuable metal into a soluble form by means of microorganisms In biooxidation, on the other hand, gold is predominantly unlocked from refractory ores in largescale stirredtank biooxidation arrangements for further processing stepsBiomining: metal recovery from ores with microorganisms

Ore Dilution Recovery in Mining

From 85 to 95 percent of the ore usually can be recovered by shrinkage stoping with dilution of 5 or 10 to 25 percent, except where some other method would be better suited to the conditions Sometimes dilution runs 30 percent or more, but in most such instances cutandfill or some other method With the presence olYFe3 H2SO4 and H3AsO4, hydrolitic reactions occur and produce various precipitates depending on the ore composition Jarosite and elemental Scould be formed These precipitates are decomposed in order to improve silver and gold extraction Refractory ore treatment by this method normally gives gold extraction in excess of 95%Treatment of carbonaceous refractory gold ores Bioleaching of Uranium: Bioleaching is the method of choice for the largescale production uranium from its ores Uranium bioleaching is widely used in India, USA, Canada and several other countries It is possible to recover uranium from low grade ores (001 to 05% uranium) Methods of Metal Recovery by Microorganisms (2 Methods)

Methods of recovering platinumgroup metals from

Because the ore is sulfidic in nature, it was concentrated by froth flotation A 45 kg/h process development unit (PDU) was constructed and 85 to 95% of the platinum and palladium were recovered from the ore by using mercaptobenzothiazole or sodium isobutyl xanthate as collectorsThe invention discloses a method for comprehensively recovering molybdenumcontaining polymetallic gold ore resources, which comprises the following steps: firstly, crushing and grinding molybdenumcontaining gold ores first, performing floatation on useful metallic elements to obtain bulk concentrate by a complete mixing floatation method, and discarding tailings; secondly, leaching out and Comprehensive recovery method of gold ore resource 1 Direct action of bacteria on the ore to extract metal 2 Bacteria produce certain substances such as sulfuric acid and ferric iron which extract the metal (indirect action) In practice, both the methods may work together for efficient recovery of metals Organisms for bioleaching:Methods of Metal Recovery by Microorganisms (2 Methods)

Recovery of platinum group metals from oxide ores—TML

The Great Dyke, Zimbabwe, contains over 800 million ounces of platinum and approximately 20 million ounces of rhodium However, about 10% of the ore is oxidized and cannot be processed with current recovery methods A conventional flotationsmelting process has been proposed to recover the platinum group metal (PGM) values from the sulfide oresBioleaching is a conversion of an insoluble valuable metal into a soluble form by means of microorganisms In biooxidation, on the other hand, gold is predominantly unlocked from refractory ores in largescale stirredtank biooxidation arrangements for further processing steps In addition to copper and gold production, biomining is also used Biomining: metal recovery from ores with microorganismsIn this paper, the effect of the oxidative pretreatment and lead nitrate addition on the cyanidation of Zarshuran refractory gold ore containing 332 ppm Au, 109% As, and 05% sulfur were (PDF) Cyanidation of Refractory Gold Ores: A Review

A Method for Leaching or Dissolving Gold From Ores or

A Method for Leaching or Dissolving Gold From Ores or Precious Metal Scrap during the precipitation stage for the recovery of gold from precious metal scrap Gold Ore with Cyanide and A MERCURYFREE METHOD OF GOLD RECOVERY Promoting viable handson solutions is the goal of our Stop Mercury Project, and direct smelting is a mercuryfree method of gold recovery from highgrade concentrates It’s a simple and costeffective method that can be done in the field with very little education, equipment or expertiseDirect Smelting Mt Baker Mining and MetalsThe Borax Method is a technique of artisanal gold mining, with its basis in the principle that borax reduces the melting point of all minerals, including precious metals like gold The melting point of gold is 1063 ˚C, which is a higher temperature than can be obtained by cheap torches and burnersGold Recovery : 8 Steps (with Pictures) Instructables

Recovery of Silver, Gold, and Lead From a Complex

Recovery of Silver, Gold, and Lead From a Complex Sulfide Ore Using Ferric Chloride, Thiourea, and Brine metal was recovered from the brine solution in an electrolytic cell with ore would be difficult Similar methods were used by Scheiner (810) to extract 3632 Analysis of gold in ore solids 364 Xray diffraction 365 BET surface area analysis 3651 Method of BET analysis 3 66 SEM analysis 37 MEASUREMENT OF MINERAL REST POTENTIAL 3 71 Construction of mineral electrodes 3 72 Measurement test procedure CHAPTER4 THE ROLE OF METALCYANIDE SPECIES IN GOLD LEACHING 81 81 82 82 85 85The leaching and adsorption behaviour of gold oresBioleaching is a conversion of an insoluble valuable metal into a soluble form by means of microorganisms In biooxidation, on the other hand, gold is predominantly unlocked from refractory ores in largescale stirredtank biooxidation arrangements for further processing steps In addition to copper and gold production, biomining is also used Biomining: metal recovery from ores with microorganisms

Recovery Refractory Resources SGS

refractory gold ore is goldcontaining ore that is resistant to recovery by direct cyanidation and carbon adsorption processes More specifically, it is an ore that has a gold recovery rate of less than 80% when direct cyanidation is applied to it Dr Chris Fleming, senior metallurgical consultant at SGS Minerals, says: “In the past two to Cyanide in solution is combined with gold ore and leaches the metal to form a soluble cyanide gold complex The gold is then typically adsorbed onto activated carbon for downstream recovery The resulting barren solution, still containing cyanide but absent of gold, can then be recycled for reuse and leaching of new oreUTILIZING CYANIDE RECOVERY TECHNIQUES IN THE A gold recovery method of the present invention includes: a gold leaching step of leaching the gold contained in a goldcontaining metal sulfide ore, while warming, into an acidic leachate containing chloride ions and/or bromide ions as an anion and copper and iron as a cation; a gold adsorption step of adsorbing the gold leached into the ACTIVATED CARBON REGENERATION METHOD AND GOLD RECOVERY

New Gold Recovery

The results of New Gold Recovery have been scientifically tested and verified by Global Mineral Research (GMR), a thirdparty metallurgical research lab, and Inspectorate Exploration and Mining Services, part of the Bureau Veritas group, all industry leaders 1 Direct action of bacteria on the ore to extract metal 2 Bacteria produce certain substances such as sulfuric acid and ferric iron which extract the metal (indirect action) In practice, both the methods may work together for efficient recovery of metals Organisms for bioleaching:Methods of Metal Recovery by Microorganisms (2 Methods) 3632 Analysis of gold in ore solids 364 Xray diffraction 365 BET surface area analysis 3651 Method of BET analysis 3 66 SEM analysis 37 MEASUREMENT OF MINERAL REST POTENTIAL 3 71 Construction of mineral electrodes 3 72 Measurement test procedure CHAPTER4 THE ROLE OF METALCYANIDE SPECIES IN GOLD LEACHING 81 81 82 82 85 85The leaching and adsorption behaviour of gold ores

(PDF) Cyanidation of Refractory Gold Ores: A Review

In this paper, the effect of the oxidative pretreatment and lead nitrate addition on the cyanidation of Zarshuran refractory gold ore containing 332 ppm Au, 109% As, and 05% sulfur were the method selection, the liability of the Aubearing ore to cyanidation is the most critical aspect In other words, the extraction possibility of gold from the given ore should be justified to consider/assess any leaching method for field scale operationBottle Roll Testing for Cyanidation of Gold Ores: Problems A method for improving the yield of gold and silver from a MerrillCrowe recovery process where the presence of copper effects yield The method involves the addition of a substoichiometric amount of ethylenediaminetetraacetic acid in combination with a phosphonate and Method of improving precious metal yield in a Merrill