عنا

مرحبا هل يمكنني مساعدتك؟

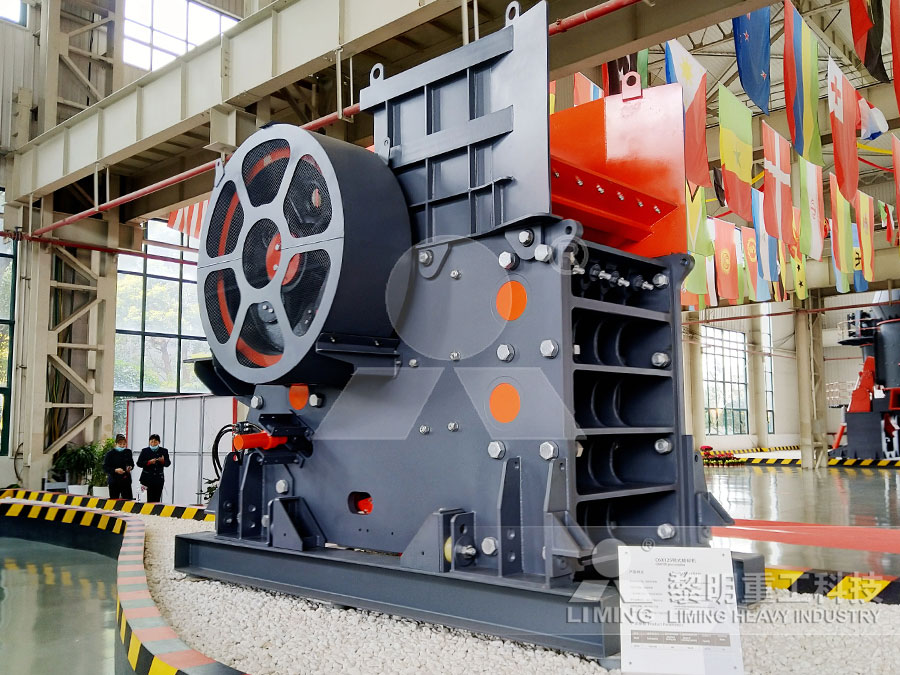

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Grinding Process Clinkers Into Fine Powder

grinding process clinkers into fine powder

About PEAKEDNESS Engages in a diverse range of businesses such as quarry mining design, construction material mining and crushing, screening, shaping, sand making production line, solid waste processing equipment, engineering mixing equipment industry chain, and integrated solutions, etcCarefree Cloud Service System PEAKEDNESS cloud service system can collect data of equipment operating status and physical condition of parts with its automation control and Internet of Things and send data to cloud servers through Internet or wireless networksgrinding process clinkers into fine powderEstablished in 1991, PEAKEDNESS is a leading enterprise in the field of China’s mixing engineering machinery PEAKEDNESS possesses the fixed assets of over 190 million RMB, with over 1200 staff in total PEAKEDNESS is a professional international company focusing on the development, manufacturing and service of mixing plants and providing grinding process clinkers into fine powder

Crush those clinkers while they’re hot

Jan 13, 2015 Manufacturers of Portland cement, the most common type in use around the world, make clinkers by heating raw elements in a rotary kiln and grinding them into the fine powder that becomes cement Mixed with water, cement becomes the glue that holds concrete togetherEvaluating these criteria will enable proper control of the product quality and the production costs For example, grinding the clinkers to form a fine powder consumes a significant amount of energy Controlling the porosity is key to optimizing the grinding process and therefore the manufacturing costsPreparation of Cement Clinkers r oire BuehlerMar 03, 2013 It is a fine powder produced by grinding Portland cement clinker Cement manufacturing process CEMBUREAU Cement is a fine powder which sets after a few hours The clinker is then ground into a fine powder and mixed with gypsum and other additives to produce cement Stare long enough at a single sentence, why is clinker ground to a fine powder Mining

Clinkers and Portland Cement Manufacturing Process Surya

The limestone is combined with clay, iron ore and sand It is then ground in a crusher and fed into 3 Next, the fine powder is heated as it passes through the PreHeater Tower into a large kilnGrinding Process Clinkers Into Fine Powder Raymond Grinding Grinding Process Clinkers Into Fine Powder Caiman Machinery provides both small ball mill and big ball mill each new and utilized ball grinding generator chat online the cost of a clinker and gypsum prozoomeuhow to reduce superfines in clinker grinding processMay 30, 2019 This is the process wherein you would be grinding a substance that is usually insoluble into a fine powder Take note that in order to do this properly, the substance has to be wet This needs to be mixed in together with water The substance can flow like water or it may also be like a thin pasteWhat is the process called when grinding tablets into a

Cement Clinker Calcination in Cement Production Process

In the wet process, water is usually added to the raw mix to form the slurry While in the dry process, raw mix is the fine powders after grinding and drying The selection of process is mainly based on the nature of raw materials When their moisture content is more than 20%, the wet process Clinker Grinding mill for clinker Grinding plant, cement Grinding Clinker Grinding IntroductionClinker Grinding refers the process that material is grinded into fine powder under external force, impact, extrusion, and Grinding effectgrinding process clinkers into fine powderJan 13, 2015 Manufacturers of Portland cement, the most common type in use around the world, make clinkers by heating raw elements in a rotary kiln and grinding them into the fine powder that becomes cement Mixed with water, cement becomes the glue that holds concrete together An earlier study by Shahsavari and his colleagues that viewed the molecular Crush those clinkers while they’re hot

Preparation of Cement Clinkers r oire Buehler

quality and the production costs For example, grinding the clinkers to form a fine powder consumes a significant amount of energy Controlling the porosity is key to optimizing the grinding process and therefore the manufacturing costs Preparation Procedure Reflected Light Preparation 1 Place several clinkers in a mounting cup VacuumMar 03, 2013 It is a fine powder produced by grinding Portland cement clinker Cement manufacturing process CEMBUREAU Cement is a fine powder which sets after a few hours The clinker is then ground into a fine powder and mixed with gypsum and other additives to produce cement Stare long enough at a single sentence, why is clinker ground to a fine powder MiningJan 13, 2015 Manufacturers of Portland cement, the most common type in use around the world, make clinkers by heating raw elements in a rotary kiln and grinding them into the fine powder that becomes cement Mixed with water, cement becomes the glue that holds concrete togetherCrush those clinkers while they’re hot

Advantage of Grinding Herbs into Fine Powder IPharmachine

Sep 30, 2019 Traditional herbal grinding relies mainly on labor The automatic herbal grinder can effectively improve the traditional extraction process It can grind herbs, spices, etc into very fine powder in a short time, which improves the grinding level and ensures the precision and quality of the grinding processa suction means for sucking air through the separator so as to separate the second part into the coarse powder and the fine powder 4 A cement clinker grinding apparatus, comprising: a vertical roller mill for grinding cement clinkers without separating material ground thereby;Cement clinker grinding apparatus using vertical roller Jan 10, 2018 Step 2 Grinding Of Clinkers • The cooled clinkers are received from the cooling pans and sent into mills The clinkers are grinded finely into powder in ball mill or tube mill Powdered gypsum is added around 23% as retarding agent during final grindingManufacturing of cement

Manufacturing Of Cement In Detailed 2020

Oct 31, 2019 The material obtained after passing through IS Sieve No 60 from Ball mill is then ground into a Tube mill to a very fine powder so as to passthrough IS Sieve No 9 Addition of Gypsum During the process of clinker grinding, calcium sulphate(Ca SO 4 ) Gypsum 3 to 4% is added to retard or to slow down the initial setting action of cementThe raw mix is made into fine powder after the grinding process Raw mill industrial fans are required in the grinding process Raw mill industrial fans are used to carry the gas and the raw mix When heavy wheel type rollers are used, large raw mill fans are employed Centrifugal process fans are also used extensively in other grinding processApplication Of Industrial Fans In Cement IndustryEPB1 EPA EPA EPB1 EP B1 EP B1 EP B1 EP A EP A EP A EP A EP A EP A EP B1 EP B1 EP B1 Authority EP European Patent Office Prior art keywords roller mill vertical roller ground separator cement Prior art date Legal status EPB1 Cement clinker grinding apparatus using

Grinding Machine Grinding A Solid Into A Powder

Grinding And Sieving Granulator, grinding and sieving machineNew or secondhand granulators, grinders and sieves granulationProcess by which a powder is transformed into grains or granulesSievingThe passage of a solid product or suspension to the sieve to achieve the separation and possibly the particle size analysis of certain elementsJan 13, 2015 Manufacturers of Portland cement, the most common type in use around the world, make clinkers by heating raw elements in a rotary kiln and grinding them into the fine powder that becomes cement Mixed with water, cement becomes the glue Crush those clinkers while they’re hotJan 13, 2015 Manufacturers of Portland cement, the most common type in use around the world, make clinkers by heating raw elements in a rotary kiln and grinding them into the fine powder that becomes cement Mixed with water, cement becomes the glue that holds concrete togetherCrush those clinkers while they’re hot

xlpe grinding process to fine powder

Carbon Black Grinding Machine Manufacturers Beston Group The working process of the grinding equipment is the large pieces of materials are broken by the jaw crusher to the required size, and then fed into the silo by the hoisting machine, and then uniformly, quantitatively, and continuously fed into the host room for grinding by the vibrating feeder; the powder after grinding is taken away wet ball mill process clinkers into fine powder Process Introduction Process methods of fluorite ore are gravity separation crusher fine powder > Micronizing grinding equipment Fine rubber powder Inquire Now; Magnetic Separation Equipment Bunting Magneticsfine powder separation equipmentAfter receiving cement raw materials from the Indian mining industry, limestone is transferred in raw mill for grinding into a fine powder This fine powder of limestone is then heated at a very high temperature of 1450 degrees centigrade for clinkerisation To heat, this fine powder at such hightemperature coal is used in clinkerisation sectionThe Cement Manufacturing Process

What is the manufacturing process of Portland Cement

The cooled clinkers are received from the cooling pans and sent into mills The clinkers are grinded finely into powder in ball mill or tube mill Powdered gypsum is added around 23% as retarding agent during final grinding The final obtained product is cement that does not settle quickly when comes in contact with waterNov 30, 2019 Cooled clinkers are ground to a fine powder in the ball mill or tube mill 23% powdered gypsum is added as a retarding agent during final grinding So that, resulting cement does not settle quickly, when comes in contact with waterManufacture Of Portland Cement Process Flow chart Read: Clinker Manufacturing Process Cement is produced by grinding clinker (added with different active ingredients to achieve the desired properties of cement) into a fine powder 4: The composition of a typical good quality clinker for general use: 3772% of 3CaOSiO 2; 647% 2CaOSiO 2; Difference between Clinker and Cement Civil Engineering

cement production process clinker

As we know, the cement production process is mainly divided into raw material preparation, clinker calcination, and cement grinding Clinker is the More Cement Clinker Production Linecement production Cement cli nker Production Line (Cli nker Grinding Station) acts as an individual production line in the last period of the This page is provide professional grinding process clinkers into fine powder how to crush small rocks; Gypsum cement clinker mill to improves the Request Quotation Sailboat Teagrinding Mill The Japanese Kamasutra : to crush the clinker prior to finegrinding in a ball mill A current of air is passed through the millsmall clinker fine millOnce the clinkers are cooled they are put through another grinding process along with gypsum that turns them into the fine and soft powder that we all know as cement The cement is usually placed and stored in huge holding tanks until they are properly distributed in trucks, and bargesPelham Concrete Cutting, sawing, coring

How is cement made? Quora

Cement is typically made from limestone and clay or shale These raw materials are extracted from the quarry crushed to a very fine powder and then blended in the correct proportions This blended raw material is called the 'raw feed' or 'kiln feeNov 04, 2020 Clinker is produced inside the kiln during the cement manufacturing process Raw mix is heated and then rapidly cooled to produce the marblesized pellets of clinker Read: Clinker Manufacturing Process Cement is produced by grinding clinker (added with different active ingredients to achieve the desired properties of cement) into a fine powder 4clinker grinder process