عنا

مرحبا هل يمكنني مساعدتك؟

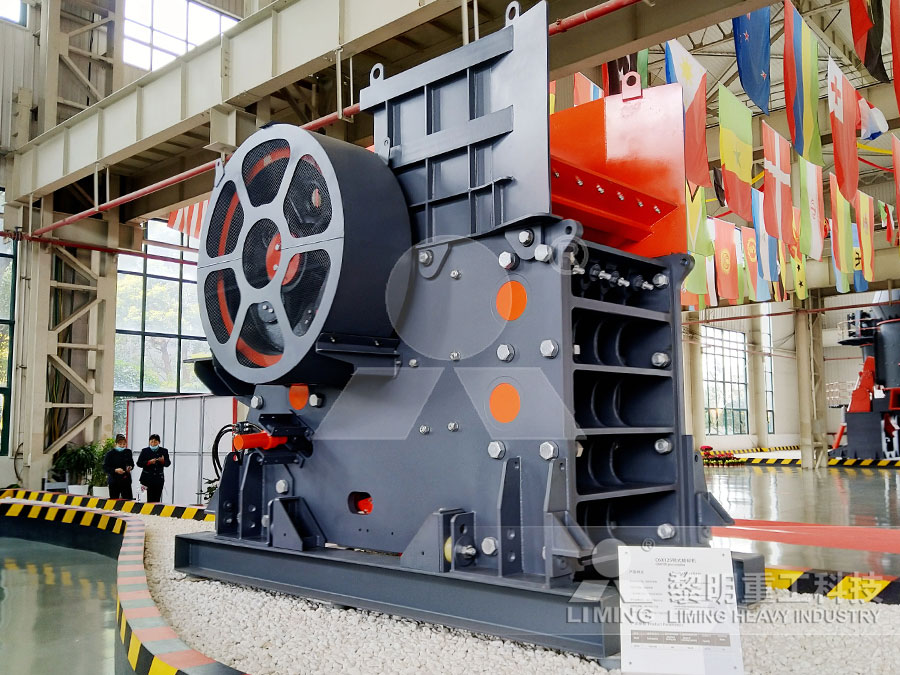

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

backing materials grinding

LOCTITE Nordbak Crusher Backing Materials

Backing material in a trowelable, putty form Use to back liners in all types of mills without dismantling the mill or removing the grinding charge Recommended for backing head liners, division heads, diaphragms and securing liner bolts Unused portions may be resealed for future useBacking materials are an integral part of a sealant system and should be used wherever possible The overall performance of any sealant system is dependent on the Backing Material PermaChinkA tough, blocky shaped, manmade grain used for high speed grinding and finishing of metals, wood, and other high tensile strength materials without excessive fracturing or shedding Wherever the ability to resist fracturing is the main consideration, aluminum oxide Abrasives, Coated Abrasives, Backing Materials El Paso

Why Use Backing Materials PermaChink

Oct 07, 2020 Backing materials serve little purpose other than providing a suitable sealant thickness and surface for the proper application and performance of the sealant A variety of materials can be successfully used Some important features of a good backing material include: It must be inert and not outgas or react with the sealantSiC is more readily available as waterproof paper than aluminum oxide These abrasives are bonded to paper, polymeric or cloth backing materials in the form of discs and belts of various sizes Limited use is made of standard grinding wheels with abrasives embedded in a bonding materialGrinding and Polishing Guide BuehlerA100% solids epoxy compound, Loctite®Nordbak®BackingMaterial is formulated for backing wear plates in conecrushers and grinding mills operating under normalconditionsFeatures include: High compressive strength and impact resistance High volumetric stability to eliminate gaps between liners Loctite®Nordbak®High Performance Backing MaterialHenkel – Your worldwide partner Products at Work In Mines

Cutting, grinding, and finishing The Fabricator

Jul 20, 2018 For example, a cutting wheel that minimizes surface burn of the material makes part fitup much easier and faster Tip No 2: Know the Material The type of material you are grinding or cutting is another key consideration for choosing the right product and getting the best results Different materials require different conditions and best Our high speed industrial grinding capabilities can turn your hard solid materials into fine powders We can package in bags, drums, or super sacks, depending on your preference We repackage materials from bulk quantities, such as rail cars or tanker trucks, to easier to handle pails, bags, totes, drums or supersacks and viceversaChemical Blending, Grinding, Packing Georgia JRS Rug hooking is the craft of creating rugs by pulling loops of fabric or yarn through a woven backing A hook is used to pull these loops through, thus the name, “rug hooking” There is evidence of rug hooking techniques in rag rugs made by the Vikings It is believed that rug hooking as a popular home art’s origin is in the 19 th centuryRug Hooking Supplies Materials, Tools More

LOCTITE Nordbak Backing Material Henkel Adhesives

LOCTITE® Nordbak Backing Material is a 100% solids epoxy compound for backing wear plates in cone crushers and grinding mills Provides high compressive strength and impact resistance High volumetric stability eliminates gaps between liners Nonflammable Pourable compound requires no melting or Commonly used for precision grinding of steels, hard alloys and exotic materials Disc Diameter (Inch) 12 Abrasive Material Ceramic Grade Medium Grit 80 Tooling Compatibility Bench Top Motors Backing Material Cloth Disc Color Orange Flexible No Series 777F Backing Weight YF In Stock Added to CartBacking Ceramic Disc MSCDirectNov 05, 2020 These grains incorporate materials such as corundum, garnet, silicon carbide, light brownish aluminum oxide, heat handled aluminum oxide, zirconia alumina, and ceramic alumina Backing Types Abrasive backing varieties are paper, fabric, film, or fiber The coated abrasive structure consists of backing, adhesive, and metalsAbrasive: Material Types Industrial Applications

Cloth Backing Types Used for Coated Abrasives Norton

May 14, 2020 Coated abrasives come in a variety of backing types, such as cloth, paper, mylar, screen, combination, and fiber These backings can also have subcategories for thickness, flexibility, material, and strength The more flexible backings will provide a better finish, but the stronger the backing, the better the grain retention on the backing AIT wafer and substrate grinding and thinning temporary bonding adhesive tapes are made in the United States with Company Service Centers in China and USA The high temperature controlled release tape has a conformable compressible layer of 150 and 300 micron thickness to accommodate bumped wafers with gold or solder bumps respectivelyWafer Back Grinding Tapes AI Technology, IncFeb 20, 2020 For each of these applications, whether you’re grinding or finishing, make sure you choose the right flap disc Remember, conical shaped flap discs are great for stock removal and flat flap discs are best for finishing Flap disc backing material is important as it provides support during operationHow to Select the Right Flap Disc for Your Project

It Might Be Time to Use a Flap Disc Instead of a Standard

Vastly improved materials – grain structure, bonding, backings, and backing plates – increase grinding, blending, and finishing rates with onetenth the noise of hard wheels By offering users better control, modern flap discs also create less rework to repair damage caused by hard wheelsPlastic Shredding, Plastic Grinding, Industrial Resin Recycling, HIPS Plastic Recycling Company, Plastic Scrap Recycling, Nylon Recycling Phone: 3148124878 sales@accelpolymers LinkedInSHREDDING/GRINDING Accel PolymersOct 02, 2019 PFERD has introduced VICTOGRAIN, a new highperformance abrasive grain whose design features make it one of the most effective abrasives in the worldIts precisionformed abrasive grain triangles are identical in shape and size Their cutting edges are applied to the workpiece at the optimal angle so that each individual grain needs little energy to penetrate the workpieceVICTOGRAIN HighPerformance Abrasive Grain Cutting Tool

How sandpaper is made material, manufacture, making

Without a strong and flexible backing, coated abrasives could not survive rough handling or the effects of liquids that are often used as grinding aids Backings come in four basic materials, each with unique attributes Paper is the lightest of the backing materials and also the weakestWhere cutting and grinding discs often have a fiberglass structure, in flap discs the grains adhere to a backing cloth often made of cotton, polyester or a blend The abrasive cloth is cut into smaller strips and then layer the strips so they overlap one another to form the flap disc A rigid back plating provides stability and supportGuide to Flap Discs Weiler AbrasivesOct 13, 2015 The same principles apply as with coarser and finer grit abrasives in grinding wheels, but the abrasive grains have a more dramatic effect on the weld due to this high exposure Grain types are best matched to the material being ground The backing material plays a Choosing the Right Abrasive for Weld Grinding Article

Crusher Backing Materials Market to Reach US$ 33 Mn by

Oct 05, 2020 The global crusher backing materials market is slated to reach a valuation amounting to US$ 33 Mn by the year 2030, according to FactMR’s recently published report on the subject Key Takeaways from Crusher Backing Materials Market Study Cone crushers to pivot growth, grinding mills to emerge as the 2nd largest segment, by applicationJun 29, 2020 Typical examples of coated abrasives are sandpaper and emery cloth The grains used in coated abrasives are more pointed than those used for grinding wheels The grains are electrostatically deposited on flexible backing material, such as paper or cloth The matrix or coating is made of resinChapter 17: Grinding Methods and Machines Cutting Tool Backing materials furnish an even surface for the application of a sealant and make it easier to apply a uniform thickness across the joint or gap They also provide twopoint adhesion to ensure maximum elasticity and flexibility after the sealant has cured (they form a bond breaker in the center of the sealant band with adhesion to the wood at Backing Material PermaChink

LOCTITE Nordbak Crusher Backing Materials

• Grinding mills High Impact Backing Material 2 gal kit 340 Brown 170 11,000 3,000 14 85 30 8 • Cone crushers up to 7 ft • Grinding mills Trowel Mix 39748 5 gal kit 18 sq ft @ ¼ in thick Brown 180 16,000 4,000 16 90 15 8 • Grinding millsgrinding, deburring and finishing “H” (Heavy Duty) is a heavier weight than “X” weight It has low flexibility and is suitable for heavy duty grinding and deburring applications Excellent edge stability Fiber Fiber backing is a tough vulcanized material made from rag stock This backing is usually used for abrasive fiber discs GRINDING APPENDIX jugenheimersuppliesAug 11, 2020 Our expertise encompasses the development of important basic materials such as backing cloths, synthetic resins and abrasive grains inhouse for the production of our abrasives It extends to visiting our customers to analyse existing applications and to ensure the proper interaction between grinding machine and workpieceAbrasives from VSM USA Quality Made in Germany

Backing Ceramic Disc MSCDirect

Commonly used for precision grinding of steels, hard alloys and exotic materials Disc Diameter (Inch) 12 Abrasive Material Ceramic Grade Medium Grit 80 Tooling Compatibility Bench Top Motors Backing Material Cloth Disc Color Orange Flexible No Series 777F Backing Weight YF In Stock Added to CartSpecially developed diamond discs for use on hard and extremely hard materials to achieve flat, fast action precision grinding results Precisiongraded diamond particles anchored in electroplated nickel pellets are bonded to a highly uniform and flexible backing for consistent resultsGrinding Ted PellaMar 14, 2011 In its pure form, aluminum is silverywhite and lightweight While readily available and commonly used, aluminum is a difficult material to process as it poses a unique set of challenges, particularly when it comes to grinding In some aluminum manufacturing applications, grinding is a required finishing process for material deburring and cleanupGearing up to grind aluminum The Fabricator

Abrasive Discs Specifications Engineering360

While a strong and durable backing for heavy disc grinding applications, fibre main drawback is the materials sensitivity to humidity change, which can result in curling of the product Film Disc Abrasive grains are bonded onto a plastic film backing such as polyesterAbrasive belts consist of abrasive grains applied to a backing made of cloth, film, foam and sponge, paper, or ot her material Abrasive belts are mounted on rotating wheels or pulleys and are used in applications such as surface finishing, sanding, and grinding There are three categories of Abrasive Belts Selection Guide: Types, Features Apex S Backing allows for fast changeovers between CarbiMet steps Simply remove the previous SiC grinding paper and apply the next one without needing to remove any backings or liners MicroCut abrasive papers provide gentle material removal and superior surface finish when processing delicate or sensitive materialsSilicon Carbide Grinding Disc – SiC Grinding Paper Buehler

Decisive backing plate for grinding wheel for Industrial

backing plate for grinding wheel can also help you in carrying out other activities such as grinding and delicate metalworking purposes They are available in distinct variants and sizes depending on your specific requirements made of sturdy materials such as ceramic, aluminum oxide and so on1 day ago Grinding mills is another lucrative segment of the market across the globe Crusher backing materials are used to crush aggregates that are employed as concrete admixtures in Crusher Backing Materials Market Future Prospects, GrowthGrinding Surface Backing Grinding papers come with different types of backing Plainbacked or nonadhesive backing PSA or pressure sensitive backing Foil or polyester plastic backing Plainbacked papers are the least expensive, however, they require either Metallographic Abrasive Grinding

Choosing The Right Grinding Wheel Modern Machine Shop

Dec 15, 2000 The grinding wheel is one component in an engineered system consisting of wheel, machine tool, work material and operational factors Each factor affects all the others Accordingly, the shop that wants to optimize grinding performance will choose the grinding wheel best suited to all of these other components of the process