عنا

مرحبا هل يمكنني مساعدتك؟

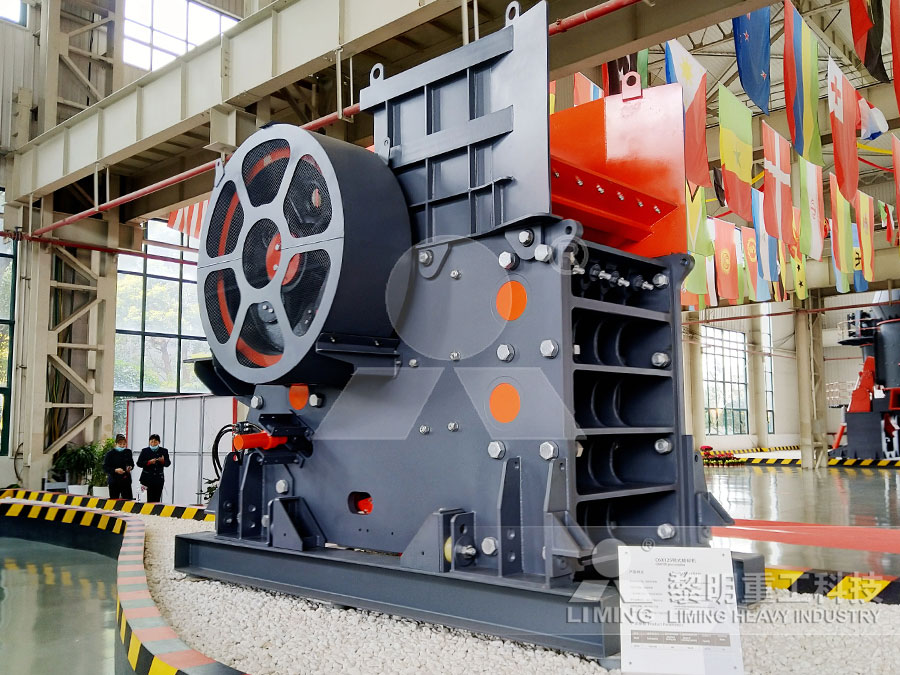

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Cement Production Process Crushing

Cement Production Process Yuhong Heavy Machinery Co,Ltd

Cement Production Process 1 Crushing In cement plant, most of the material needs to be broken, such as limestone, clay, iron ore and coal, etc Limestone is the largest amount of raw material in cement production, so the crushing stage plays a very important role in cement plant 2 Raw material grindingManufacturing process flow 1 Quarrying and Crushing The quarry (where the mining activity is performed) is located 07 km away from the plant and has the manufacture of Portland cement Gypsum and Pozzolana are going to be used for final cement hammer crusher which can crush 550ton/hour The crusher reduces 85% of the rock lumps from a Manufacturing process flow 1 Quarrying and CrushingA Cement manufacturing Process Source:civilengineeringforumme The whole process of cement manufacturing in Messebo Cement plant which consists of crushing) and Clinker storage 7 Cement grinding and storage 8 Cement packing and Dispatch Figure 1: Process and Quality Flow DiagramCEMENT PRODUCTION AND QUALITY CONTROL A Cement

Cement Making Process Cement Production Process Cement

We offer cement projects with various capacities and production purposes, such as large scale cement production lines, mini cement plants, cement grinding units, stone crushing plants, etc We apply the advanced predecomposition technique in our dry method cement production lines, which reduces the energy consumption in the cement making processCement Production Process 1 Crushing In cement plant, most of the material needs to be broken, such as limestone, clay, iron ore and coal, etc Limestone is the largest amount of raw material in cement production, so the crushing stage plays a very important role in cement Cement Production Process Yuhong Heavy Machinery Co,LtdIn cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc Limestone is the largest amount of raw material during cement productionCement Crushing Grinding Plant,

CEMENT PRODUCTION AND QUALITY CONTROL A Cement

A Cement manufacturing Process Source:civilengineeringforumme The whole process of cement manufacturing in Messebo Cement plant which consists of crushing) and Clinker storage 7 Cement grinding and storage 8 Cement packing and Dispatch Figure 1: Process and Quality Flow DiagramCement production process flow diagram Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Cement production process flow diagram, quarry, aggregate, and different kinds of mineralsCement production process flow diagramThe raw material preparation comprises of the following operations: Crushing PreHomogenization (Stockpiling) Raw material proportioning, drying and grinding Blending and kiln feed Crushing Crushing can be defined as comminution (size reduction) process to reduce the size of Run of mine (ROM) Limestone/sandstone to size (1030mm cement manufacturing

(PDF) THE CEMENT MANUFACTURING PROCESS Junaid Younis

THE CEMENT MANUFACTURING PROCESS Prof Dr Elshafie Ahmed Gad Faculty of Applied Science Chemistry Dept Portland Cement Portland cement is made by mixing substances containing CaCO3 with substances containing SiO2, Al2O3, Fe2O3 and heating them to a clinker which is subsequently ground to powder and mixed with 26 % gypsum Raw Materials Necessary for Portland Cement Feb 01, 2021 Cement Manufacturing Process Flow Chart 1Crushing In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc Limestone is the main raw material for cement production, each producing a ton of clinker needs about 13 tons of limestone, more than 80 of raw material is limestoneManufacturing Process Of Lime From Limestone Production Cement is made from common materials such as limestone, clay, silica, and iron ore that are blended together Click on the circles above and tour Continental Cement’s Hannibal plant to view the cement making process For a more detailed description of the cement manufacturing process, visit Portland Cement Association’s presentationManufacturing Process – Continental Cement

How Cement Is Made Portland Cement Association

Cement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet processA clean and revolutionary cold manufacturing process Hoffmann Green has initiated a technological breakthrough based on changing the composition of cement so that it does not contain clinker, the main source of CO2 emissions in traditional cement production, as well as creating a cold and clean cement manufacturing process (no firing of raw materials)The manufacturing process Hoffmann Green CementsSep 27, 2019 Cement manufacturing process In general, we can divide the cement production line into three main steps: raw material preparation of cement, clinker production, and finished cement Each step has some cement manufacturing machines, such as raw mill, cement crusher, cement mill, cement kiln, cement cooler, cement dryer, cement silo, packing Cement Euipment Overview Cement Making Machines Cement

Dry Process Of Cement Manufacturing\Dry Process Of Cement

Oct 29, 2019 Dry process method means manufacturing raw materials into raw materials powder, whose water content is generally less than 1% So, the dry process can `reduces heat loss needed by heating and autoclaving water But the dry process has its own flaw that is the bad fluidity of materials grain in a kiln It will cause an uneven mixTechnological Prehomogenization:Crushing: during the process of cement production,most of the raw materials need to be crushed,such as lime stone、clay、iron ore、coal etc Limestone is the largest amount raw material for cement production,the particle size is bigger and the hardness is higher, so the limestone crushing have an important position at the material crushing of cement plantMainly technological process of 5000t/d cement production lineThe cement manufacturing process in the plant can be divided into seven steps: Step 1 – Raw Material Crushing Pre Homogenization: In the Portland cement manufacturing process, most raw materials need to be crushed first, such as limestone, clay, iron ore, and coalPortland Cement Plant for Sale New Dry Process of

b Crushing Cement Production

Crushers Operation of a jaw crusher A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism The jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until it is small Aug 25, 2020 The Portland cement manufacturing process is representative of all types of cement limestone and clay are the main raw materials of cement making, the cement raw materials will be processed into a raw meal by crushing, batching, grindingCement Production Process Cement Manufacturing Process Jul 20, 2020 P ortland cement is by far the most common type of cement in general use around the world This articles looks at the cement manufacturing process in 4 steps Step 1: Mining The first step of Cement manufacturing process is to quarry the principal raw materials, mainly limestone, clay, and other materials Step 2: CrushingCement manufacturing process: Stepbystep guide CCE l

Crushercement production processlvssn

Crusher Max feeding size: 420600(mm) Output size: 150(mm) Application: cement me tallurgy sand aggregate industry Limestone crushing production line is an important li nk in burnt lime production line and cement production line Enable Ginger Cannot connect to Ginger Check your internet connection or reload the browser Disable in this text field Edit Edit in Ginger Edit in Ginger × rame THE CEMENT MANUFACTURING PROCESS Prof Dr Elshafie Ahmed Gad Faculty of Applied Science Chemistry Dept Portland Cement Portland cement is made by mixing substances containing CaCO3 with substances containing SiO2, Al2O3, Fe2O3 and heating them to a clinker which is subsequently ground to powder and mixed with 26 % gypsum Raw Materials Necessary for Portland Cement (PDF) THE CEMENT MANUFACTURING PROCESS Junaid Younis The raw material preparation comprises of the following operations: Crushing PreHomogenization (Stockpiling) Raw material proportioning, drying and grinding Blending and kiln feed Crushing Crushing can be defined as comminution (size reduction) process to reduce the size of Run of mine (ROM) Limestone/sandstone to size (1030mm cement manufacturing

Cement Manufacturing Process Phases Flow Chart

Aug 30, 2012 Crusher reduces the size of large rocks to the size of gravels Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding Generally Cement is made from common materials such as limestone, clay, silica, and iron ore that are blended together Click on the circles above and tour Continental Cement’s Hannibal plant to view the cement making process For a more detailed description of the cement manufacturing process, visit Portland Cement Association’s presentationManufacturing Process – Continental CementThe limestone most suitable for cement production must have some ingredients in specified quantities ie, calcium carbonates, silica, alumina, iron,etc Belt Conveyors The quarried raw material is transported to the cement plant, using mechanical conveying equipment such as ropeways or belt conveyors, or by vehicles like wagons and trucksCement Production Process SlideShare

The diagrams illustrate the steps of how cement production

The diagrams illustrate the steps of how cement production process, and how to use cement to produce concrete for construction work Overall, it can be seen that the cement making process undergoes five stages and it can used for building purposes by three materials added with cementCEMENT PLANT USING CLINKER (CRUSHING PLANT) Project Report Manufacturing Process Cost Investment Required Report includes feasibility report, profitability analysis, raw materials, break even points, formulations and formula and much moreProject Report on CEMENT PLANT USING CLINKER (CRUSHING Hammer crusher Max feeding siz: 5001200(mm) Capacity: 1003000t Inlet Size: 250×4001200×1500(mm) Applied material: pebbles granite basalt limestone and etc Hammer crusher is one of the main equipment for crushing limestone coal or other brittle materials in me tallurgy building materials chemical industry hydropower and other industriesThe hammer crusher produced by our company is Hammer crushercement production processlvssn

Cement Plant Cement Manufacturing Plant EPC Project

The cement manufacturing plant can be divided into five steps: Crushing prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them; Raw material preparation: use cement mill to process materials into required sizes for cement clinker production; Clinker production: In the cyclone preheater system, the raw material powder Oct 29, 2019 Dry process method means manufacturing raw materials into raw materials powder, whose water content is generally less than 1% So, the dry process can `reduces heat loss needed by heating and autoclaving water But the dry process has its own flaw that is the bad fluidity of materials grain in a kiln It will cause an uneven mixDry Process Of Cement Manufacturing\Dry Process Of Cement