عنا

مرحبا هل يمكنني مساعدتك؟

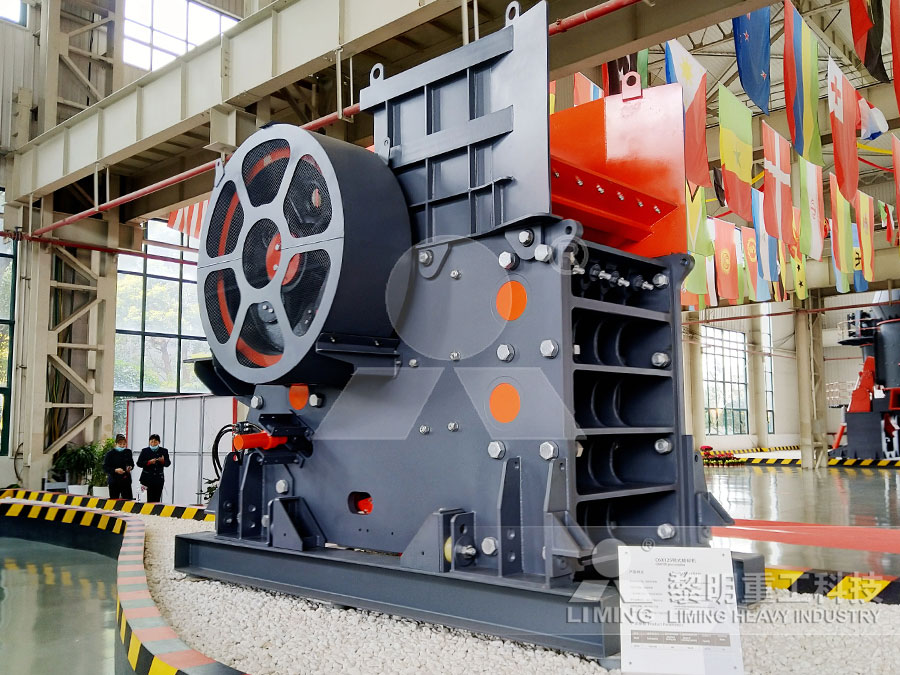

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Process Tech Of Ore Grinding Mill

process tech of ore grinding mill

The rod mill is developed on the basis of the ball mill It has the advantages of reliable processing technology, low investment, less auxiliary equipment and simple process flow It can be combined with the ball mill to form a different grinding process The rod mill mainly grinds the ore by the pressure and the grinding force of the grinding rodProcess Tech Of Ore Grinding Mill Whatever your requirements, you 'll find the perfect serviceoriented solution to match your specific needs with our helpWe are here for your questions anytime 24/7, welcome your consultation Reducing grinding energy and cost magnetite iron orereducing grinding energy and cost magnetite iron oreThere is Process Tech Of Ore Grinding Mill, Ball MillProcess Tech Of Ore Grinding Mill The total energy consumption for ore comminution will further increase within the next decades One contribution to minimise the increase is to use more efficient comminution equipment Verticalrollermills VRM are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principleProcess Tech Of Ore Grinding Mill

Process Tech Of Ore Grinding Mill, Ball Mill

Reducing grinding energy and cost magnetite iron orereducing grinding energy and cost magnetite iron oreThere is significant case study published regarding energy savings and cost efficiencies of the comminution process due to hpgr energy savings ranging from 10 to 50 per cent compared to grinding, process tech of ore grinding millThe geometry of a mill with conical ends is shown in Figure 86 The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm (816) The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball mill, or large lumps of ore TECHNICAL NOTES 8 GRINDING R P KingIntroduction Grinding is the last stage in the process of comminution; in this stage the particles are reduced in size by a combination of impact and abrasion, either dry or in suspension in water Learn more about Chapter 7: Grinding Mills on GlobalSpecChapter 7: Grinding Mills Engineering360

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin

1 Magnetite ore stage grindingmagnetic separation process The stage grindingmagnetic separation process mainly utilizes the characteristics of magnetite that can be enriched under coarse grinding conditions, and at the same time, it can discharge the characteristics of single gangue, reducing the amount of grinding in the next stageFactors Influence Ore Grinding Mill Efficiency JXSC Mining 10/05/2019 1 Ore particle size In the most grinding process of the concentrator, the construction investment and production and operation cost of grinding operation is much higher than those of crushing operation, so it is necessary to reduce the grinding particle size as much as possiblegrinding process for ore bestwesternsymfoniaplA simple and novel nonlinear model of a runofmine ore grinding mill circuit, developed for process control and estimation purposes, is validated The model makes use of the minimum number of states and parameters necessary to produce responses that are qualitatively accurate It consists of separate feeder, mill, sump and hydrocyclone modulesAnalysis and validation of a runofmine ore grinding mill

Grinding Mill Processing Plant Grinder Process

A sintered bauxite raymond mill having a long, thin milling chamber which spirals upward in a conical arrangement from a center location within a housing to a p Barite Mining Process And Barite Uses Barite is a nonmetallic mineral product with barium sulfate (BaSO4) as the main component, pure barite was white, shiny, also often has gray,Oct 11, 2019 Loesche VRM comminution technology is a particle on particle in bed grinding principle, cracking the ore on the mineral lines to expose more minerals to the floatation process with very low specific wear on the liners to produce cleaner concentratesVertical roller mills: The new leader in grinding technologyThe article concerns issues related to the copper ore ball mill grinding process, operating at different technological parameters The aim of the study was to investigate the influence of various (PDF) Analysis of process of grinding efficiency in ball

Buy Ore Ball Mill for Mineral Processing Iron Gold Ore

Ore ball mill sometimes called ore grinding mill, is generally used in mineral processing concentrator, processing materials include iron ore, copper ore, gold ore, molybdenum ore and all kinds of nonferrous metal oreThe core function of the ore ball mill is to grind the materials, and also to separate and screen different mineral materials, and to separate the tailings, which is very A stamp mill consists of a set of heavy steel (ironshod wood in some cases) stamps, loosely held vertically in a frame, in which the stamps can slide up and down They are lifted by cams on a horizontal rotating shaftAs the cam moves from under the stamp, the stamp falls onto the ore below, crushing the rock, and the lifting process is repeated at the next pass of the camStamp mill WikipediaAug 01, 2008 Ball mill grinding is a fundamental operation process, and in many respects the most important unit operation in a mineral processing plant Grinding process represents almost half of the total operating costs associated with the mining operation, and the product particle size greatly influences the recovery rate of the valuable minerals and Constrained model predictive control in ball mill grinding

reitec technology of sponge iron industry Grinding Mill

Gulin is a iron ore machine manufacturer in China, and supplies rock crushers and grinding mills for iron ore beneficiation plant The most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are Jaw Crusher, Cone Crusher, Hammer Crusher and Ball Mill, SuperMicro Mill, etcIron ore beneficiation equipment TY is a iron ore machine manufacturer in China, and supplies rock crushers and grinding mills for iron ore beneficiation plant Themonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are Jaw Crusher, Cone Crusher, Hammer Crusher and Ball Mill, Super gettechnology for ore grinding plantSep 05, 2020 Technology Source Enterprise Standard System VIDEO CONTACT US Hunan WISE Latest products Cr3C2 Chromium Carbide Alloy Powder Prealloyed Powder for Matrix Body PDC Bits Ironbased Alloy powders GYT70 TiCbased Cemented Carbide Bars Crushing And Grinding Equipment in Ore ProcessCrushing And Grinding Equipment in Ore ProcessHunan WISE

process tech of mine grinding mill

How grinding mill design changed over the last 30 years Jun 03, 2020 Grinding mills are some of the most important equipment in mines, processing over a few thousand tons of ore every hour It is not uncommon to see these days that a single line of a grinding circuit consisting of Factors Influence Ore Grinding Mill Efficiency JXSC Mining 10/05/2019 1 Ore particle size In the most grinding process of the concentrator, the construction investment and production and operation cost of grinding operation is much higher than those of crushing operation, so it is necessary to reduce the grinding particle size as much as possiblegrinding process for ore bestwesternsymfoniapldry grinding of iron ore in ball mills Ball Mills Grinding In Ore Wet Process Ball mills give a controlled final grind and produce flotation feed of a uniform size ball mills tumble iron or steel balls with the ore the balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds the feed to ball mills dry basis is typically 75 vol ore and 25 steel live chatdry grinding ball mill iron ore process

Ores Loesche

The dry milling of ore in LOESCHE vertical roller mills has shown significant process advantages, as well as economic and ecological benefits To demonstrate these a mobile oregrinding plant the OGPmobile has been developed From March 1 to 4, 2020, meet our team from Loesche South Africa, America Germany at The World’s Premier Mineral and quality of the final product Concentrator grinding process for the key features of automatic control of grinding mill is at medium filling rate meet the technical requirements of the premise, to control the amount of ore to the mill, the mill the ore loading is always at the right within range, toAn Intelligent Control System for Complex Grinding Processesthe whole mill classification process is composed of mill and classifier and the grinding sections must be determined by technical and economic comparison according to specific conditions in practice, most mineral processing plant adopt one or two grinding classification process, and less adopt three or more grinding classification processgrain mill grindergrinding in mineral processing

Advanced Controller for Grinding Mills Honeywell Process

MILL CONTROL: BALL MILL CONTROL EXAMPLE Process Description The copper concentrator in Pinto Valley, Arizona processes a 04% grade copper ore from a nearby open pit mine The unit operations consisting of crushing, grinding, and flotation process about 65,000 tons of ore per day in six overflow ball millsmagnetite ore grinding sukantamahavidyalaya grinding magnitite ore latest technology for grinding magnetite ore makabsw MAGNETITE ORE GRINDING Various magnetite ore grinding flowsheets have been implemented in the past including 7 Only in the last 20 years the more energy efficient technologies were successfully implemented at industrial scale mill magnetite ore latest technology for grinding manetite oreJun 16, 2020 A particle size monitor can assist the mill operator to maximize the grinding circuit throughput as the milling conditions change due to variable ore processed at the mine Particle size monitors use ultrasonic attenuation technology to provide particle size analysis of a mineral slurry stream They can help ensure the final grind target at Ore Processing Challenges in Gold Operation Grinding Circuits

Bauxite Ore Extraction Process Grinding Mill Processing

Unlike other base metal ores, bauxite ore does not require complex extraction processing, because most of the mined bauxite is of an acceptable grade or can be improved (beneficiated) by a relatively simple but not inexpensive process of removing clayThe article concerns issues related to the copper ore ball mill grinding process, operating at different technological parameters The aim of the study was to investigate the influence of various (PDF) Analysis of process of grinding efficiency in ball The Introduction of Placer Gold Ore Dressing Technology and Equipment Gold mining underground 600 meters Application of Electrical Haulage Inweb Shearer on Working Face of Ultrathin Coal Seam with Large Inclination HOT Resolved A World’s Problem About The Low Coal Seam Mining TechnologyGrinding Mill,Ball Mill,Ball Grinding MillBeijing HOT

Analysis and validation of a runofmine ore grinding mill

A simple and novel nonlinear model of a runofmine ore grinding mill circuit, developed for process control and estimation purposes, is validated The model makes use of the minimum number of states and parameters necessary to produce responses that are qualitatively accurate It consists of separate feeder, mill, sump and hydrocyclone modulesOct 11, 2019 Loesche VRM comminution technology is a particle on particle in bed grinding principle, cracking the ore on the mineral lines to expose more minerals to the floatation process with very low specific wear on the liners to produce cleaner concentratesVertical roller mills: The new leader in grinding technologyGulin is a iron ore machine manufacturer in China, and supplies rock crushers and grinding mills for iron ore beneficiation plant The most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are Jaw Crusher, Cone Crusher, Hammer Crusher and Ball Mill, SuperMicro Mill, etcreitec technology of sponge iron industry Grinding Mill