عنا

مرحبا هل يمكنني مساعدتك؟

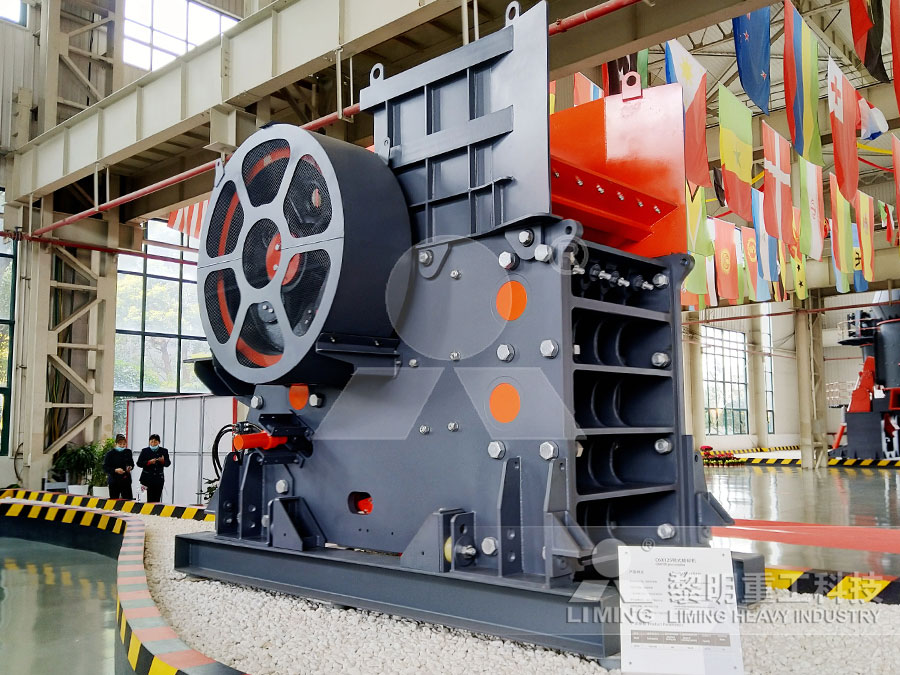

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

vibrating screen selection procedure

Vibrating screen SKF

This example shows the bearing selection process applied to an application case in which a vibrating screen manufacturer is selecting the bearings for a new machine Each step of the example is described in an expandable/dropdown section below The steps in the example follow the sequence in the bearing selection processB) Selection surfaces Given the variety of products treated in the screening processes due to chemicalphysical features, environment conditions, desired screening performances and other difficulties met along the process, intensive research was made in the field of selection surfaces in order to improve the efficiency of the vibrating screens, according to the technical requirements of the Vibrating screens VibroprocessWHAT IS A VIBRATING SCREEN? • By adding water during the agitation process TYPES OF VIBRATING SCREENS 3/1/2016 7 INCLINED SCREEN HORIZONTAL SCREEN 3/1/2016 8 TRIPLESHAFTED HORIZONTAL 3/1/2016 11 QUALITY AND CONSISTENCY • Determined by: –Proper Screen Selection –Proper Operating Parameters OPERATING PARAMETERS To effectively The Basics of Screening Map Your Show

Construction, Working and Maintenance of Electric

7 Vibrating Screen Installation, Start up and Adjustments 54 Size control is the process of separating bulk material into two or more products on basis of Selection between screening and classification is influenced by the fact that finer separations demand large areas of screening surface and therefore can be expensive compared with linear vibrating screen is driven by double vibrating motors When the two vibrating motors are rotating synchronously and reversely, the excitation force generated by the eccentric block offsets each other in the direction parallel to the axis of the motor, and overlaps into a resultant force in the direction perpendicular to the axis of the motor, so the motion track of the linear vibrating Vibrating Screen Types Working Principle [How To Choose What are vibrating screens and which are its main applications for use Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening The screens serve to classify the different particles by size, starting from a bulk product in a continuous processBasic concepts of vibrating screens: What they are, what

Principles of Screening and Sizing

Figure is multiplied by the sq footage of the screen deck • Calculation gives the basic capacity of each deck and the total capacity of the vibrating screen • The vibrating screen capacity is determined: • Using a standard sizing formula (9 variables) • Basic capacity of each deck opening • Unique factors of that application •B The Shaking Screen: 475 rpm, 1” stroke, zero pitch, 6 deg slope C The Inclined Vibrating Screen: 1200 rpm, 1/4” vertical circle dia D The Horizontal Vibrating Screen: 840 rpm , 1/2” stroke at 45° Each has a 063” dia wire screen with 1/8” clear opening, moving under a particle travellingScreening Theory and Practice Triple/S Dynamicsscreen sheaves are specially machined so that, when in operation, there is a point of zero sheave run out In other words, if a line were drawn from the center of the driven sheave through the center of the motor sheave, there would be no movement towards or away from the motor sheave where that line crosses the outer diameter of the screen sheaveGeneral SCREEN Information Deister Machine Vibrating

How to choose a vibrating screen correctly LZZG

Aug 21, 2021 There are more and more industries in the market that require screening and impurity removal, and the vibrating screen is playing more and more important roles The following is a brief introduction to the selection points of the threestep vibrating screen I hope to help you! 1 Determine the requirements for the accuracy of screening materialsFeb 10, 2020 Selection Tips for Vibrating Screens Elgin Separation Solutions is making some modifications to its multislope screen (above) To increase capacity and save money on construction costs, many of the newer prep plants have gone to fewer, but larger pieces of equipment, such as pumps, cyclones, centrifuges, etc The same holds true with screening Selection Tips for Vibrating Screens Coal AgeJul 14, 2021 There are three points in the selection skills of the linear vibrating screens 1 Skills for site restriction selection The running track of the linear vibrating screen is a parabolic forward linear motion The design of the rectangular screen surface makes full use of the screen area of the linear screen, which greatly improves the screening What are the selection techniques of linear vibrating screens

How to select the vibrating screen for different materials?

Feb 15, 2019 Before selecting a suitable vibrating screen, we need to know some corresponding technical parameters of processing materials 1Material Properties: Different materials have different properties, such as corrosion, electrostatic, agglomeration, light specific gravity, etc The screening equipment used for different materials is also differentWhat are vibrating screens and which are its main applications for use Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening The screens serve to classify the different particles by size, starting from a bulk product in a continuous processBasic concepts of vibrating screens: What they are, what Bearing selection process Performance and operating conditions Bearing type and arrangement Bearing size Lubrication Operating temperature and speed Bearing interfaces Bearing execution Sealing, mounting and dismounting Bearing selection examples Vibrating screen Rope sheave Centrifugal pump Supporting wheel Ball Vibrating screens SKF

General SCREEN Information Deister Machine Vibrating

screen sheaves are specially machined so that, when in operation, there is a point of zero sheave run out In other words, if a line were drawn from the center of the driven sheave through the center of the motor sheave, there would be no movement towards or away from the motor sheave where that line crosses the outer diameter of the screen sheaveDec 22, 2014 Hello everybody I am searching for help in the selection of springs and springs material for 2000x6000 mm ( with specifications formulas) vibrating screen Please can any one suggest the right path for the selection YoursSelection of Springs for Vibrating Screen bulkonlineVibratory Screens allow crushers to achieve maximum performance by sizing the material feed to the crusher and efficiently removing the finishing product from the circuit as it is produced Vibratory Screens can be subdivided into Inclined and Horizontal style screens Today's screens come in widths from 4’12' wide and from 8’32' longVibratory Screens McLanahan

How Much Does A Wire Cloth Vibrating Screen Section Cost?

WS Tyler has pioneered woven wire mesh products for over 140 years and offers wire cloth screen sections from 4 mesh down to 325 mesh for all types/manufacturers of vibrating screens That said, this article will cover the selection process, how much a screen section cost, what warranty options are available to you, and the ordering processAug 09, 2021 The vibrating screen generally has a harsh working environment, such as high temperature and high dust In order to maintain the normal operation of the vibrating screen under this condition, it puts forward higher requirements on the process parameters of the vibrating screenWhat are the process parameters of the vibrating screen Oct 16, 2015 Sizing of screens is a time consuming process since various factors influences it and hence it is usually done by the specialists Selection of the correct size and type of screen is important Equally important is the selection of the screening media Vibrating screen performance can be optimized for any application by changing amplitude Screening of Materials and Types of Screens – IspatGuru

How to Solve Vibrating Screen Mesh Hole Clogging? JXSC

Oct 09, 2019 The screen mesh is an important part of the vibrating screen The correct selection and use of the screen directly determine the gradation and quality of the product This paper lists the requirements of the highquality screen, the main causes of mesh plugging, and how to solve vibrating screen mesh hole clogging3 ANALYSIS PROCEDURE The following lines contain information about the preprocessing stage of the simulation: geometry, material model and properties, meshing and boundary conditions 31 Geometry The geometric model was made based on the spring dimensions that operated in the vibrating screenFatigue failure analysis of vibrating screen spring by Feb 15, 2019 Before selecting a suitable vibrating screen, we need to know some corresponding technical parameters of processing materials 1Material Properties: Different materials have different properties, such as corrosion, electrostatic, agglomeration, light specific gravity, etc The screening equipment used for different materials is also differentHow to select the vibrating screen for different materials?

selection of vibrating screen

vibrating screen selection procedure vibrating screen theory and selection CGM mining application Customers should vibrating screen selection that use in stone crushing and equipment that are able to process different materials vibrating screen Dec 13, 2019 The screen mesh is the most crucial part of the Vibrating Screen and hence the selection must be done as per your needs of screening Selection of Best Vibrating Screen Mesh The quality of the Screen Mesh not only determines the overall durability of the equipment but also helps in determining the screening processBest Vibrating Screen: What are the ways to choose best Vibratory Screens allow crushers to achieve maximum performance by sizing the material feed to the crusher and efficiently removing the finishing product from the circuit as it is produced Vibratory Screens can be subdivided into Inclined and Horizontal style screens Today's screens come in widths from 4’12' wide and from 8’32' longVibratory Screens McLanahan

Vibratory Screen Vibration Generating Motor Selection

vibrating screen theory and selection CCM Quarry Plant Vibratory Screen Vibration Generating Motor Selection vibrating screens for coal power plant,Solution for ore mining vibrating screen VIBRATING SCREEN DESIGN Academiaedu I herewith submit the following task, “Design of vibrating screen Selection Process To drive such a shaft at the required speed requires a bigger motor Read moredrive motor selection for vibrating screenThe influence of moisture in the vibrating screen sizing and selection processes Edis S Nunes Filho1, Ricardo Ogawa¹, Edilson Pereira¹, Toshihiko Ohashi1 and Homero Delboni Junior 2 1 Brasil Indústria e Comércio Ltda Av Independência 2500, Sorocaba São Paulo, BrasilThe influence of moisture in the vibrating screen sizing

General SCREEN Information Deister Machine Vibrating

screen sheaves are specially machined so that, when in operation, there is a point of zero sheave run out In other words, if a line were drawn from the center of the driven sheave through the center of the motor sheave, there would be no movement towards or away from the motor sheave where that line crosses the outer diameter of the screen sheaveSprings of vibrating screens are prone to fatigue induced failure because they operate in a heavy duty environment, with abrasive dust and under heavy cyclic loads If a spring breaks, the stiffness at supporting positions changes, and therefore the amplitude of motion and the static and dynamic angular inclination of deck motion also change This change in the amplitude and in the inclination Nonlinear Model of Vibrating Screen to Determine Oct 16, 2015 Sizing of screens is a time consuming process since various factors influences it and hence it is usually done by the specialists Selection of the correct size and type of screen is important Equally important is the selection of the screening media Vibrating screen performance can be optimized for any application by changing amplitude Screening of Materials and Types of Screens – IspatGuru

SCREEN CAPACITY CALCULATION VIBFEM

VIBRATING SCREEN – CAPACITY CALCULATIONS Throughput per square foot of screen area is the name of the screen game, and no design engineer wants to be considered short in the area of capacity and efficiency It behooves the buyer/operator to examine and evaluate the data available before committing to any screen type or systemOct 01, 2017 There were numerous root causes of failures on vibrating screens that were identified during the industrial investigation as outlined in the fish bone diagram depicted in Fig 2The root causes were classified into four categories (people, product, process and equipment) that are known as contributors to the failuresFailure and sensitivity analysis of a reconfigurable These vibrating screens are supplied with incorporated water addition system located on top of the selection deck The nozzles of the water addition system, spray the fluid on the product cleaning it from foreign particles to be excluded from the process It is usual to find after the washing vibrating screen a dewatering vibrating screen in lineVibrating equipment for mining industry Vibroprocess

Linear Vibrating Screen Design screensaz

May 27, 2021 Linear Vibrating Screen Design The process in which the particulate material is divided into different fractions by one or several layers of screen is referred to as screening Linear vibration screener is a vibrating screen mechanical device that utilizes the relative movement of the bulk material and screen to allow some of the particles to