عنا

مرحبا هل يمكنني مساعدتك؟

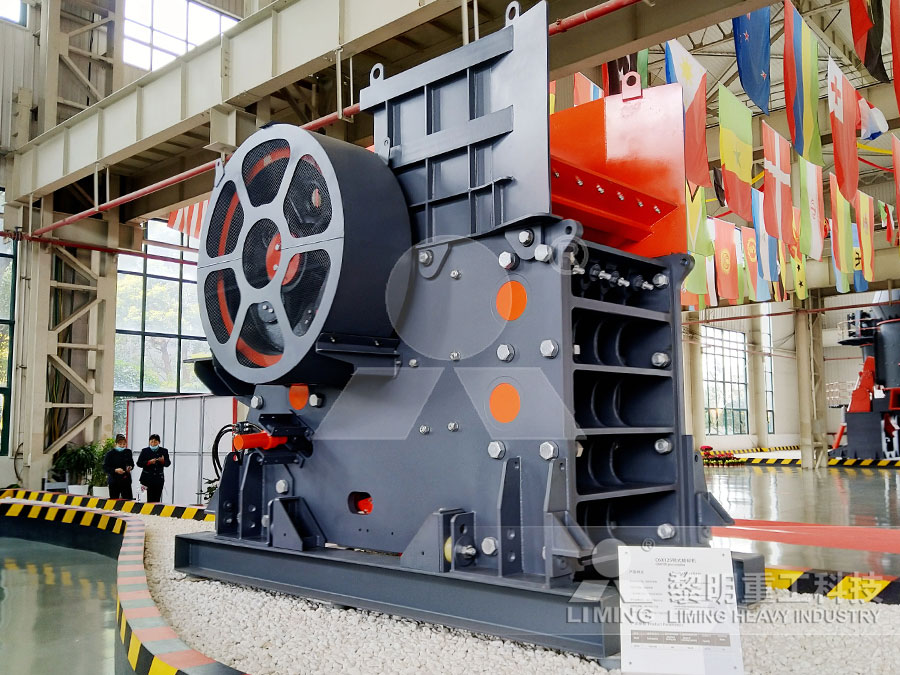

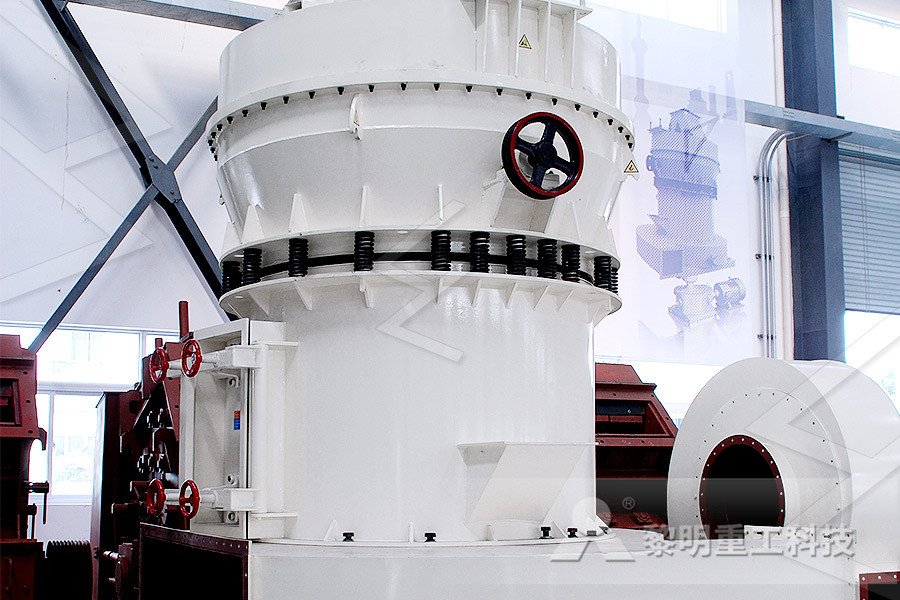

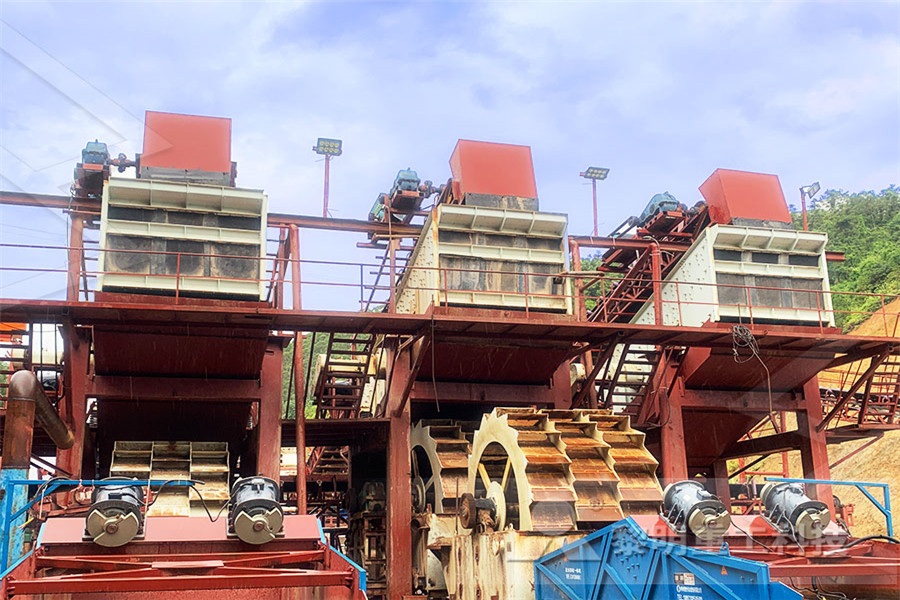

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

methods of operating crushers

Methods of operating crushers

Methods of operating crushers Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Methods of operating crushersA method of operating a rotorequipped breaker/crusher for coal and other material in which the drum is rotated at close to critical speed, and in which lifter shelves in the drum are adjusted for dropping material into the path of the rotor at a point where the rotor not only fragments the material, but also emphasizes the flinging of the material against the downwardly moving perforated wall About this siteA method of operating a rotorequipped breaker/crusher for coal and other material in which the drum is rotated at close to critical speed, and in which lifter shelves in the drum are adjusted for dropping material into the path of the rotor at a point where the rotor not only fragments the material, but also emphasizes the flinging of the material against the downwardly moving perforated wall of the drumMethod of operating breaker/crusher Pennsylvania Crusher

Construction, Working and Maintenance of Crushers for

A standard testing method for comparing the relative abrasiveness of rocks, minerals and ores Cage A screening device, made of precisely spaced bars or slotted plate, where final sizing is accomplished within the crusher Choke Feed Operating the crusher with a completely filled crushing chamber Choking Stoppage of the flow of material Dynamic impact is the crushing method used by Pennsylvania Crusher Impactors Attrition Attrition is a term applied to the reduction of material by scrubbing it between two hard surfaces Hammermills operate with close clearances between the hammers and the screen bars and they Handbook of Crushingmethods of operating crushers stone crusher machine Vermiculite Grinding Mill of excellent quality real Vermiculite Grinding Mill is the equipment specializing in producing fine and superfine powder of noninflammable, nonexplosive and brittle materials with Moh's hardness under six, such as calcite, chalk, limestone, dolomite, kaolin methods of operating crushers stone crusher machine

Crushing Screening Plant

Jul 12, 2016 Methods used in Crushing Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher, screens, and rolls or cone crushers Crushing is done underground at a few large mines In general, the jaw crusher is the most suitable primary machine, yet many gyratories do the first breakingStandard operating procedure for crusher Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Standard operating procedure for crusher, quarry, aggregate, and different kinds of mineralsStandard operating procedure for crusherDec 26, 2015 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing in Mineral Processing

Crushers QueensMineDesignWiki

There are two categories of crushers based on the way the force is applied to the material For crushers of the first category apply force via pressure, the crushers of the second category apply force via impact In underground mine operations, size reduction is necessary to facilitate the transport of the material to the millMay 26, 2014 A method for operating a mineral material crusher, a system including a crusher, and a crushing plant The mineral material crusher, includes a first crushing element and a second crushing element, defining a crusher gap therebetween The crusher gap is maintained using at least one hydraulic cylinder, the hydraulic liquid pressure in at least one of the hydraulic cylinders is measured US Patent for Method for operating a crusher, a crushing Engineering Control Method: Wet Methods AND Operator Isolation The use of water sprays or mists for dust suppression at the points where dust is generated (eg, hoppers, conveyers, sieves/ sizing or vibrating components, and discharge points) can control dust exposures when operating crushers In addition, operatorFactSheet

Method Statement for Material Crushing Builders Safety

Dec 03, 2013 Method Statement for the crushing of rock and or demolition material on site using a dedicated material crusher This document is to be read in conjunction with all operating procedures supplied by the manufacturer/supplier These will apply to the operation of crushers Aug 28, 2021 4 Types of Stone Crushers' Maintenance and Efficient Improvement There are different types of stone crushers in mining industry such as jaw crusher, cone crusher, impact crusher, and sand making machine This article will tell you how to maintain the 4 types of rock crushers and how to efficicently improve their performance Many stone crusher 4 Types of Stone Crushers' Maintenance and Efficient Jul 12, 2016 Methods used in Crushing Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher, screens, and rolls or cone crushers Crushing is done underground at a few large mines In general, the jaw crusher is the most suitable primary machine, yet many gyratories do the first breakingCrushing Screening Plant

Methodology Of Vsi Crusher

Methods of operating crushers vsi crushers operating principles vsi crushers operating principles methods of operating crushers Crusher Wikipedia, the free encyclopedia 1 Background history 2 ppt on safe operating procedure of jaw crusher Gold Ore Crusher Download Jaw Crusher Pitman The pitman is the main moving Know how toStandard operating procedure for crusher Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Standard operating procedure for crusher, quarry, aggregate, and different kinds of mineralsStandard operating procedure for crusherFeb 17, 2016 Gyratory Crushers The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig 5 It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501)Gyratory Crushers Mineral Processing Metallurgy

(PDF) SIZE REDUCTION BY CRUSHING METHODS

crushers and cone crushers whereas rod m ills The operating stages in minerals process ing have remained the same These methods are adopted one after the other in sequence and also new materials and design methods, continuous development of the products Jaw gyratory crushers – design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only It is normally serrated and, toIndustrial Solutions Gyratory crushersexcluded from the bucket operating arc If the crusher is to be fed directly by a conveyor: All dangerous parts of machinery should be suitably guarded Failure to replace guards (on crushers and conveyors) after cleaning or maintenance work is a major cause of injury on these mach 15 Blocked Crushers National Federation of Demolition Contractors The voice

HSE Quarries Safe operation and use of mobile jaw crushers

Ensure pedestrians and obstructions are excluded from the bucket operating arc If the crusher is to be fed directly by a conveyor: All dangerous parts of machinery should be suitably guarded Failure to replace guards (on crushers and conveyors) after cleaning or maintenance work is a major cause of injury on these machinesThe Methods of Distinguishing the Quality of Crusher Wear Parts Discussion in 'Fanart' started by novoevid, Aug 24, 2021 at 2:07 AMThe Methods of Distinguishing the Quality of Crusher Wear The Methods of Distinguishing the Quality of Crusher Wear Parts Optimized maintenance is a key competitive advantage for an aggregate producer Dealing with multiple service providers and brands can become a significant risk as response times, quality and inventories vary across suppliersThe Methods of Distinguishing the Quality of Crusher Wear

Method Statement for Material Crushing Builders Safety

Dec 03, 2013 Method Statement for the crushing of rock and or demolition material on site using a dedicated material crusher This document is to be read in conjunction with all operating procedures supplied by the manufacturer/supplier These will apply to the operation of crushers May 26, 2014 A method for operating a mineral material crusher, a system including a crusher, and a crushing plant The mineral material crusher, includes a first crushing element and a second crushing element, defining a crusher gap therebetween The crusher gap is maintained using at least one hydraulic cylinder, the hydraulic liquid pressure in at least one of the hydraulic cylinders is measured US Patent for Method for operating a crusher, a crushing Nov 28, 2018 Crushers are used in the mining industry, construction, and other sectors to break large rocks down into smaller, more manageable pieces There is a wide range of crushers available that employ different physical methods to achieve this goalTips for Crusher Maintenance Thomasnet

Crusher Maintenance WOMP

“A key component in maximizing the crusher’s lifespan, preventive maintenance is the best method of keeping a crusher in good operating condition for a long period and will include scheduled checks, inspections and services at regular time intervals (daily, weekly, monthly, yearly), as recommended by the crusher manufacturer39 Item Part No Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)QH441OperationManual Crusher Worksnew materials and design methods, continuous development of the products Jaw gyratory crushers – design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only It is normally serrated and, toIndustrial Solutions Gyratory crushers

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

Feb 25, 2019 Avoid Unplanned Downtime: 5 Crusher Maintenance Best Practices Too many companies don’t invest enough into their equipment maintenance, and ignoring maintenance issues doesn’t make the problems go away “According to leading aggregate producers, repairs and maintenance labor average 30 to 35 percent of direct operating costs,” says Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushingCone crusher basics in 4 minutes — SRPexcluded from the bucket operating arc If the crusher is to be fed directly by a conveyor: All dangerous parts of machinery should be suitably guarded Failure to replace guards (on crushers and conveyors) after cleaning or maintenance work is a major cause of injury on these mach 15 Blocked Crushers National Federation of Demolition Contractors The voice

The Methods of Distinguishing the Quality of Crusher Wear

The Methods of Distinguishing the Quality of Crusher Wear Parts Discussion in 'Fanart' started by novoevid, Aug 24, 2021 at 2:07 AMCurrent manual methods of determining the CSS/OSS are inaccurate, dangerous and require that the equipment be shut down for at least an hour, which results in production losses In contrast, Crusher Vision can measure CSS/OSS when the crusher is operating, but empty, allowing an operator to obtain results within a few minutesCrusher Closed / Open Side Setting Program Global Practically in all metallurgical treatment the raw product needs to be crushed by crushing machines The main indicator of the crushers quality, which characterize their technical level and competitiveness, is their reliability and durability in the operating conditions, which can be quantitatively assessed by the number of failures in the process of obtaining the finished product on the machineProblems and methods of improving the quality of jaw crushers

4 Types of Stone Crushers' Maintenance and Efficient

Aug 28, 2021 4 Types of Stone Crushers' Maintenance and Efficient Improvement There are different types of stone crushers in mining industry such as jaw crusher, cone crusher, impact crusher, and sand making machine This article will tell you how to maintain the 4 types of rock crushers and how to efficicently improve their performance Many stone crusher Mar 11, 2015 CONTENTS Introduction 11 Scope of Guidance 12 Key Risks 13 Typical Layouts 14 Feeding 15 Blocked Crushers 16 Prevention 17 Action when a crusher NFDC Safe Use of Mobile Crushers Screening Plant by