عنا

مرحبا هل يمكنني مساعدتك؟

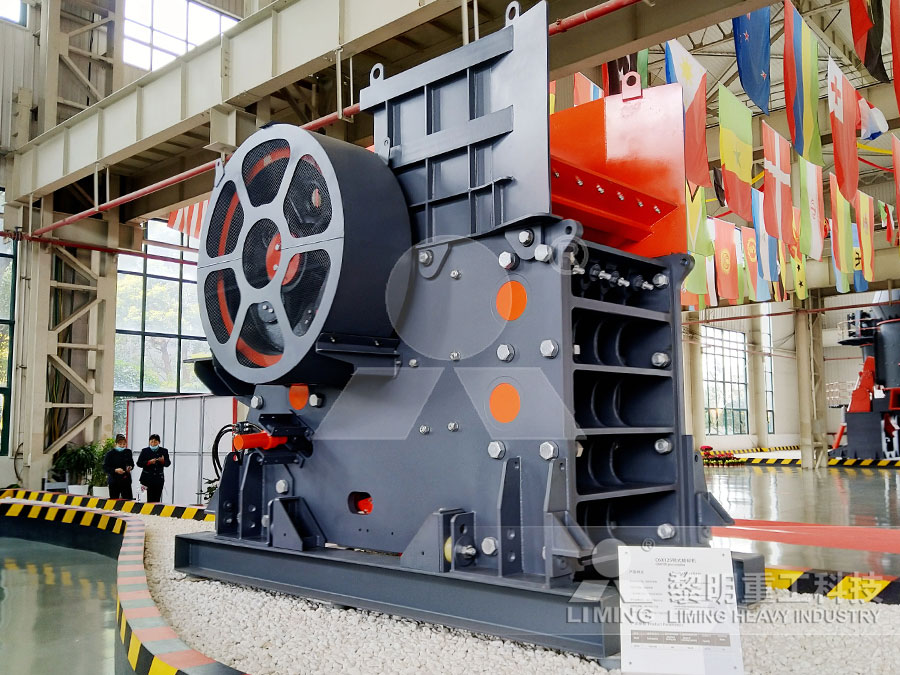

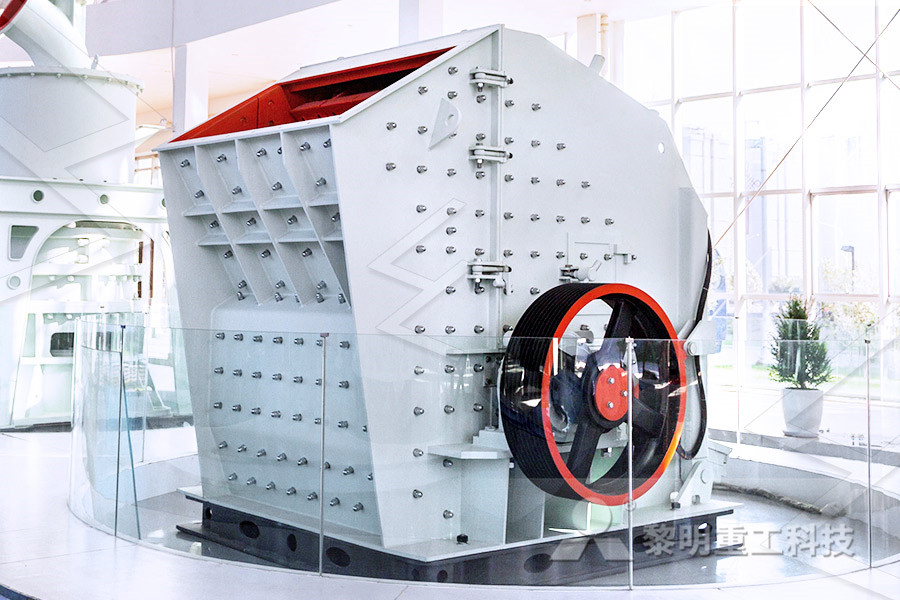

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

main part of the hammer mill

Function of the components part of hammer mill

components of the new hammer mill are Inlet tray, Throat, Magnetic chamber, Rotor, Crushing chamber, the same function as that of the huge hammer mills used in the industries, as well as the The major area of focus of this design is to More details» Get Price Eliminator Hammermill A hammer mill is mainly composed of 3 parts, the feed hopper, the pulverizing room (includes rotator, hammers, screener, toothed plates), and the discharge part (includes wind blower, aggregate cylinder, dust bag) The working principle of a hammer millWhat are the types of hammer mill?Jun 16, 2020 The part of a hammer that strikes to different surfaces is called the face Again, the diameter of a hammer’s head varies between different hammers Some hammers may have a small face whereas some have a large face like the sledge hammer Claw hammers usually have neither small nor large face, it falls in betweenParts of a Hammer (with Diagram) What They are Used for

What is the main factors affecting the Feed Mill Silo

What is the main factors affecting the working performance of hammer mill? The crushing section is one of the key sections of the feed mill production and is a large energyconsuming plant of the feed mill The work quality of the section is directly related to final products quality, output and cost of the feed millA hammer mill is essentially a steel drum containing a vertical or horizontal rotating shaft or drum on which hammers are mounted The hammers are free to swing on the ends of the cross, or fixed to the central rotor The rotor is spun at a high speed inside the drum while material is fed into a feed hopperHammermill WikipediaThe hammer mill is an impact mill employing a high speed rotating disc, to which are fixed a number of hammer bars which are swung outwards by centrifugal forceDesign and Fabrication Of Hammer Mill Mechanical Project

Replacement Hammers for Hammer Mills Schutte Hammermill

Feb 24, 2016 Description Depending on the application, hammers have either two or four wearing edges to provide maximum wear life Hammers should be rotated when the cutting edge is well rounded and the machine is not running at top performance Hammers should always be replaced in Main parts of a cone mill A Cone Mill Hopper Unprocessed material like crystals, powder or even tablets is placed on the product hopper This is can be done by use of the hand, vacuum feed or gravity feed Basically, this is the place where the matter to be milled is placed in the cone millsCone Mills: The Ultimate Guide SaintyTecHammer Mills for Wood Pellet Plant » 2011 » July the hammer Mill is a machine that grates materials into smaller constituent parts Hammer mills are used in various functions The hammer mill is different parts of hammer mill and their functions

MF2048 Hammermills and Roller Mills KSRE Bookstore

of the main motor Hammer Design through the screen holes become part of a fluidized bed of slaved to the amperage load of the main motor of the roller mill The rolls that make up a pair will be 9 to 12 inches (23 to 305 cm) in diameter, and their ratio of length toHammer mills for many applications The quality and knowhow inherent in hammer mills are backed by over a century of experience in the feed milling and other related industries around the world The requirements for grinding a large number of special products have led to the development of hammer mills that can be adaptedHammer mills Highperformance grindingA hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little hammersThese machines have numerous industrial applications, including: Ethanol plants (grains); A farm machine, which mills grain into coarse flour to be fed to livestock; Fluff pulp defiberizing; Fruit juice production; Grinding used shipping pallets for mulchHammermill Wikipedia

Hammermill Hammers CPM

Ordering Information We have every part you need to keep your hammermill running smoothly Contact us today for replacement or backup parts, and be sure you're getting exactly the piece you need To order parts from our parts specialists, call 18003662563 or fill out the form below If you are authorized to order parts online, click hereHammer Mill From dry saw dust to powder Up to 32 t/h High capacity Low energy consumption Direct or indirect coupling Bidirectional rotor The robust design of PromillStolz hammer mills allows to reach high level of quality and output, for a large range of applications Parts and materials are chosen to fulfill specific needs, in order to optimize their lifetime (hammers, screens, body)Hammer mills Promill Stolz PDF Catalogs Technical Screens Standard screen hole size: 1/4″, 5/16″, and 3/8″ (other sizes available) Productivity: Moisture of 25% to 28%, Screen size of 5/16″ 200 hp = 1 ton per minute Moisture of 13% to 15% , Screen size of 1/18″ 200 hp = 1 ton every 2 to 4 minutes Hammer Mill production will vary depending on three factors: Moisture in grain Stationary Model 4120 Lancaster Parts Equipment

Welcome PD Hammermill Spare Parts

Welcome at our website PD Hammermill Spare Parts is producer of all the spareparts for the (hammer)milling industries We produce the hammers, screens, mixerpaddles en axles for the (hammer)mills which are used for producing (animal)feed, Biomass and recyclingindustries On this website you can find all the information regarding our activities If you have any questions Hammer Mill Hammers, Screens, Rods, and Spacers Applying tungsten carbide to the leading edge of hammer mill hammers is not new, but the EXACT placement and distribution of the tungsten particles during the manufacturing process is new, and can be done only using special equipment and having the technical knowhowJacobs Corp Hammermill Pellet Mill Replacement PartsThe main components for waterpowered stamp mills – water wheels, cams, and hammers – were known in the Hellenistic era in the Eastern Mediterranean region Ancient cams are in evidence in early waterpowered automata from the third century BC A passage in the Natural History of the Roman scholar Pliny (NH 1823) indicates that waterdriven pestles had become fairly widespread in Italy by Stamp mill Wikipedia

OperatOr and parts Manual Hammermill

When Ordering Parts Always give your dealer the Model, Color and Serial Number of your machine to assist him in ordering and obtaining the correct parts Use the exploded view and tabular listing of the area of interest to exactly identify the required part Item Part Number Description Qty 1 MAIN BODY WELDT HM 1 2 HOPPER WELDT HM 1A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little hammersThese machines have numerous industrial applications, including: Ethanol plants (grains); A farm machine, which mills grain into coarse flour to be fed to livestock; Fluff pulp defiberizing; Fruit juice production; Grinding used shipping pallets for mulchHammermill WikipediaHammer mills for many applications The quality and knowhow inherent in hammer mills are backed by over a century of experience in the feed milling and other related industries around the world The requirements for grinding a large number of special products have led to the development of hammer mills that can be adaptedHammer mills Highperformance grinding

Hammer Mills CSE Bliss Manufacturing Hammer Mills

CSE Bliss hammer mills come standard with Dodge Imperial Bearings these bearings are two pieces that house a spherical roller bearing with a taper lock to secure the bearing to the shaft Internal Wear Parts: CSE Bliss has easily replaceable wear plates to assure protection of the housing to give the hammer mill a longer lifeThe major working part of hammer mill is rotor with hammer The motor will generate rotor to complete the highspeed rotation within the wide crushing chamber Materials are coming into hammer mill through the upper inlet, then they are striked and impacted by highspeed rotating hammer and gradually become small size particlesFeed Hammer Mill with Large CapacityHammer Mills come in variety of sizes for different industries Our machines are primarily designed to cater to grinding grains such as corn, wheat, and barley However, we might be able to help you with other grinding needs you might have Please call our team at (717) 2993721 with any questions or requests for custom grinding applications or Hammer Mills Lancaster Parts Equipment

Hammermill tip speed adjustment alters particle size

Apr 26, 2018 Hammermill tip speed adjustment alters particle size without downtime Particle size range for a hammermill screen size can be adjusted through manipulation of the hammer tip speed, which is made possible by the use of motor variable frequency drives The hammermill is a costeffective method of reducing particle sizes of grains for feeding075 HP FITZPATRICK Fitz Mill Comminutor Hammer Mill Model D 075 HP FITZPATRICK Fitz Mill Comminutor Hammer Mill 10 HP Shredder SHRED PAX Model AZ7 with Drive Base, Infeed Chute, Motor 10 HP Densifier PolyMax 2500 with a 15 HP Grinder PolyHog 450 10 HP Jaw Crusher Whitelaw Model 5 x 12Used Hammer Mills PROCESSCOStock #:PM37274 Stock:1 Details Add to cart 26'' SPROUT Several Parts for Model 26W300 Several spare Parts for SPROUT Gear Pellet Mill Model 26W350 See the list in Details Model 26W300 Stock #:PM15521Pellet Mills Parts PROCESSCO

MPL400 operation manualpdf GMCMPL300D Small Moveable

If the wear parts are wornout, change them but first cut the power off Don’t open the upper shell if the hammer mill is running 3135 After checking, close the upper shell and match the upper body with the lower body Tighten the safety locks and turn to the main shaftJun 22, 2017 The main goal of grinding ingredients (either with a hammer mill or a roller mill) is to maximize the value of the feed delivered to pigs By reducing particle size, corn passing through the digestive tract of the pig will be more effectively exposed to digestive enzymes, and improves the quantity of nutrients that pigs can extract from the grainRoller versus hammer: Corn particle size impacts hammer mill’s main drive motor to the feeder motor to adjust the feeder speed This will ensure that the feeder does not supply the hammer mill with more material than the hammer mill’s main drive motor can tolerate With the capability of constant adjustment through the feeder’s variablespeed drive, it is possible to avoid overloaFEED AND BIOFUEL POCKET FEEDER ANDRITZ

What Is A Hammer Mill Grinder How Does It Work?

A hammer mill grinder is designed to reduce bulk material into smaller pieces, These machines have been around for nearly a century and are still an essential part of the grain processing industry Back to main topic: Rice and Cereal ProcessingNov 20, 2020 In the study of the working mill, insufficiently treated is the problem of the hammer construction, the main working organs of the mill, which have a decisive influence on the working regime The paper emphasized the effects of the construction of hammer and it is underlined the necessity to respect the existence of one centre of percussionDependence Between the Percussion Centre and the