عنا

مرحبا هل يمكنني مساعدتك؟

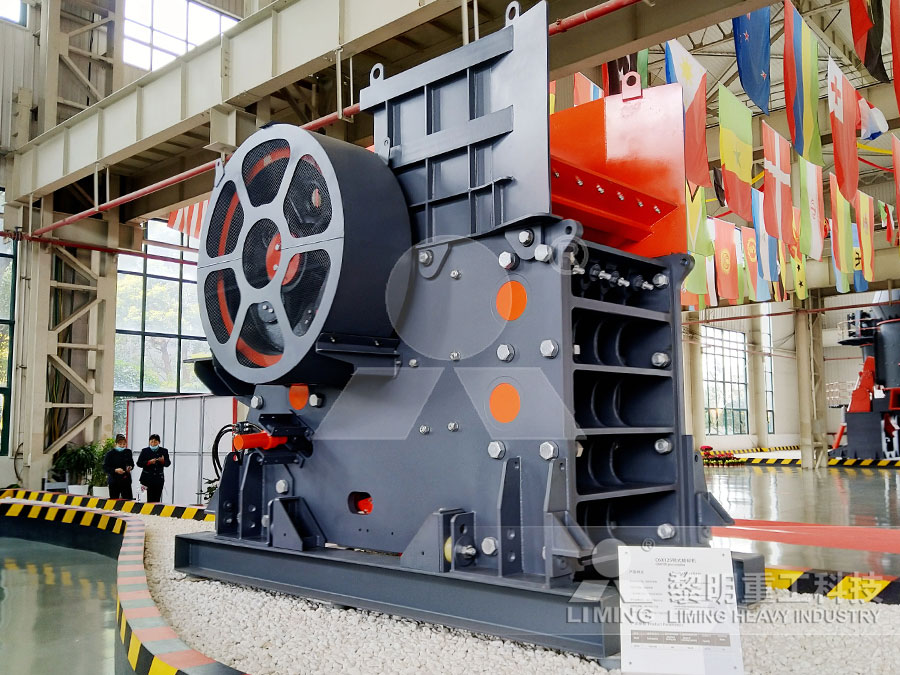

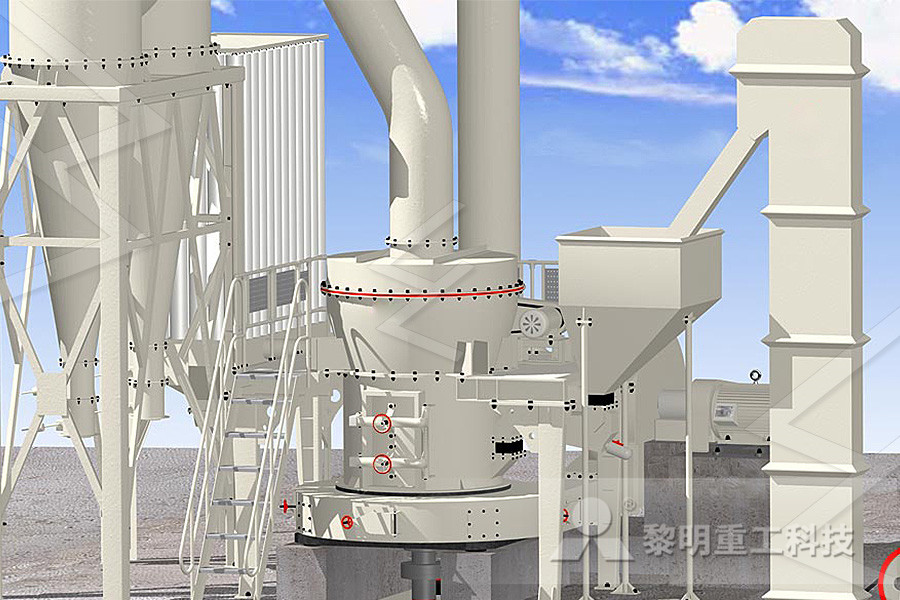

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

al grinding mill type and nfiguration

coal grinding mill type and configuration

85e coal mill ball type Posted atMarch 9 2013 49 2877 Ratings coal mill ball type coal grinding mill type and configuration Coal processing system E Mill Gear Box for Coal Grinding in Power Plants Elecon have manufactured and supplied Get Price Configuration Of Jaw Crusher Machine Coal Vertical MillThe analysis of individual mill design and operation is complex; so, for simplicity we will consider a typical mill layout for one mill type only As VSMs have come to represent the bulk of the power station mill fleet, the explanation of mill operations will be based on this mill type Figure 132 illustrates the typical key components of a VSMCoal Mill an overview ScienceDirect TopicsFor coal mill, you have several types to choose Ball mill is widely used in mineral grinding mill industry Ball mill has simple structure, low cost, high capacity and convenient maintenance Vertical coal mill is also called LM series vertical roller mill, and is also widely used in mineral grinding mill industry Vertical coal mill is big in coal pulverising mill types Grinding Mill China

COAL PULVERIZER DESIGN UPGRADES TO MEET THE

The MPS mill is classified as an airswept, pressurized, vertical spindle, table/roller mill It containsan integral classifier, a grinding section, a windbox (plenum), and auxiliary components (Figure 1)Jan 23, 2018 The vertical spindle mill crushes coal by feeding it between a grinding roller and either a bowl, table or ring at the bottom Coal enters via the coal feed and falls into the grinding zone, where it is crushed by the grinding wheelsCoalmill optimisation in coalfired power stations aids Jun 07, 2018 Coal Mills are the Heart of a Coal Fired Plant reject area, pyrite area or primary air inlet wind box depending on the type of mill Fogging and deluge systems can be very effective at “washing” away hazards under the grinding zone Coal mill system design and configurationProtective systems provide forgiveness and additional Mill Inerting Systems Presentation to the ASBCUG

Cage Mill Design, Configuration, and Application

Feb 28, 2020 By changing the speeds of the cages, the same multirow cage mill configuration can produce a variety of differentsized final products from coal, oat hulls, sugar, oyster, clam, and seashell feeds Sixrow cage mills are a unique solution for fine grinding of calcium carbonate, talc, cosmetic powders, and kaolin clayPulverizers / Mills Reliable coal pulverizer performance is essential for sustained fullload operation of today's power plants An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW BW's pulverizers, found at power stations throughout the worldPulverizers / Mills Babcock WilcoxThe ELtype pulverizer is also much less prone to coal dribble problems due to an improved bottom grinding ring and throat configuration (see Figure 3) The Etype pulverizer can be upgraded to the EL design at one time, or it can be upgraded in stages The most economical time to upgrade to the EL design is when a grinding zonePS410 E and EL Pulverizer Modifications for Optimum

Coal Mill an overview ScienceDirect Topics

The analysis of individual mill design and operation is complex; so, for simplicity we will consider a typical mill layout for one mill type only As VSMs have come to represent the bulk of the power station mill fleet, the explanation of mill operations will be based on this mill type Figure 132 May 01, 1990 Task 33, Pitt Mill Configuration Studies, was completed during this period This report presents the results of the last experiments in Task 33 which investigated effects of agitator speed, loss of grinding media, transient profiles for particle size and ash content inside the prototype, effects of grinding chamber aspect ratio, and a number of other parameters which affect screw performancePitt Mill Demonstration (Technical Report) OSTIGOVJun 07, 2018 Coal Mills are the Heart of a Coal Fired Plant reject area, pyrite area or primary air inlet wind box depending on the type of mill Fogging and deluge systems can be very effective at “washing” away hazards under the grinding zone Coal mill system design and configurationProtective systems provide Mill Inerting Systems Presentation to the ASBCUG

A Comparison of Three Types of Coal Pulverizers

installations since 1980, FLS has successfully placed in operation their own VRM's, grinding coal or raw meal, with mill capacities ranging from 7 to 300 tons per hour The following is a brief description of these three kinds of Rileysupplied pulverizers and fuel systemsThe grinding track carrier is used for the torsionproof and rigid connection to the output flange of the gearbox with 20 M48 bolts It transfers the torque At the time, the grinding track carrier must support the load force and the weight of parts inside the mill Total weight = 155 Toncoal mill Mill (Grinding) ScrewThe ELtype pulverizer is also much less prone to coal dribble problems due to an improved bottom grinding ring and throat configuration The Etype pulverizer can be upgraded to the EL design at one time, or it can be upgraded in stagesCEType Pulverizer Parts, Services, and Programs

Variable Frequency Drive In Coal Grinding Mill

Loeschemills is employed for coal grinding mills and mills in the cement and industrial minerals industry 2 3 4 or even 6 grinding roller configurations for a single grinding table can be realised the first type lm 263 d modular coal grinding mills were developed in 1980 and employed for View DetailsMay 20, 2013 hot air required coal mill zgm123g iii coal mill specification coal grinding mill type and configuration noise level in a roller mill amazon wet and dry mill grinders – Hotsale Products ZGM123G Roller Mill worldcrushersJun 21, 2019 The type of mill and circuit configuration used are essential factors in maximizing the grade and recovery profile of an ore, and so are selected on a casebycase basis Vertimills are one of the Grinding down energy consumption in comminution

What is the selection and configuration of the Raymond

Potash feldspar ore has rich market value and can be used in many fields after being ground by a grinding mill What mill manufacturers provide high output of Kfeldspar grinding mill? Guikuang(GuiLin Mining Machinery Co, Ltd) is a professional mJan 23, 2018 In addition there is heated combustion air fed to the mill to transport the pulverised coal, and the secondary air supply as shown in Fig 4 Grinding The grinding function reduces coal fed into the mill into a dust with particles of the size required for combustion There are two main types of mill in common use: the spindle type and the drum Coalmill optimisation in coalfired power stations aids for coal mills which type of grinding media is use grinding balls use in power plants grinding media in ball tube coal mill skwbaueu coal grinding mill type and configuration Introduction: Grinding Mills Stirred Media Detritor The type of mill and coal grinding mills and mills to be use to set up a coal mining What is We are Grinding Media manufacturer provide Custom Mining for coal mill which type of grinding media is use

Hyper Pressure V Type Grinder Products for Sale Sell

Production capacity: 0540T/H Notice: this capacity is mean value capacity, and the specific production capacity is subject to clients’ actual equipment configuration Processable Material PowerFor coal mill, you have several types to choose Ball mill is widely used in mineral grinding mill industry Ball mill has simple structure, low cost, high capacity and convenient maintenance Vertical coal mill is also called LM series vertical roller mill, and is also widely used in mineral grinding mill industry Vertical coal mill is big in types of conveyor systems coal Grinding Mill ChinaGE’s PVPRO mill upgrade system uses a patented process for better control of coal fineness and reduced pulverizer wear for extended operations Up to 6x life extension HCX2* ceramic inserted grinding elements significantly extend operating time between overhauls Up to 35x life extension over high chrome and high chrome overlayBoiler Mill and Coal Pulverizer Performance GE Steam Power

TPS Coal Mills and Fan Performance SlideShare

May 08, 2019 • Each type has a different grinding mechanism and different operating characteristics • There are four unit operations going concurrently within the mill body, coal drying, transport, classification and grinding • For coal pulverizers the capacity of a mill is normally specified as tonnes output when grinding coal with a HGI of 50 coal grinding mill type and configuration Grinding Mills Stirred Media Detritor The type of mill and coal grinding mills and mills to be use to set up a coal mining What is Get Price 150TPH coal mobile crusher plantKefid for coal 150tph mills which type of grinding media is use May 20, 2013 hot air required coal mill zgm123g iii coal mill specification coal grinding mill type and configuration noise level in a roller mill amazon wet and dry mill grinders – ZGM123G Roller Mill worldcrushers

Attrition Dry Milling In Continuous And Batch Modes

concept that includes a new grinding tank internal configuration and side discharge screen which allows mills to run at higher speed, using smaller media, and continuously discharges product out of the mill by centrifugal force (Fig 5) Figure 5 HSA Attritors generally operate from 4001800 RPM using grinding beads from 13mmDRIVE: Bradley mills are Vbelt driven which allow optimization of mill speed to ensure operation is quiet and output is maximized as well as easier maintenance as compared to oil or water cooled gearboxes FEED: Ground level grinding zone allows for a lowlevel Airswept Roller Mills Bradley Pulverizer CompanyAn optimum pulverizer throat configuration is a big deal The pulverizer throat area and configuration must be right to minimize coal rejects at the optimum air/fuel ratio; must help turn down to a minimum load without “rumble”; and must be configured to not have quiescent zones that contribute to mill firesPulverizer Optimization Components Storm Technologies, Inc

Pulverised Fuel an overview ScienceDirect Topics

The wet coal is fed into a pulverizer along with hot gases drawn from the firing hood The hot gas temperature is controlled by bleed air The coal or coke is simultaneously dried and ground in the hotair swept pulverizer The pulverizer can be a hammer mill, ringroll mill, or a ball mill typeMay 07, 2021 Coal gangue belongs to solid waste What equipment is used in the production line of comprehensive utilization of coal gangue? As a manufacturer, HCMilling (Guilin Hongcheng) has rich experience in flour production and manufacturing, and also provides tailormade selection scheme to meet the project production The new generation of vertical roller mill is a special grinding mill for Coal Gangue Comprehensive Utilization Grinding Mill It can be applied to the grinding and processing of coal gangue The HLM vertical mill can grind materials with a water content of 20% to 30% to a water content of less than 1%, and is highly adaptable to materials The product fineness can be adjusted from 25mm to 15μm with a pass rate of 97%ADVANCED COAL GANGUE VERTICAL MILLS HCM Grinding Mill

Simple introduction of lattice type ball mill

Ball mill is the key equipment for secondary grinding after crushing And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding Besides, it is Hammer Crusher 【 Capacity 】1100 TPH 【Feeding Size】≤350 mm 【Application】Hammer crusher can crush medium hardness and brittle materials, such as limestone, slag, coke, coal, etc Our hammer crushers are widely used in mining, cement, coal, metallurgy, building materials, highway, combustion, and other industries 【Our Services】Hammer Crusher Industry Hammer Mills JXSC Machine